In the Know: Supply logistics

In the Know is a monthly partnership between LP Gas magazine and Propane Resources. Our focus this month is on supply logistics, addressed by supply expert Tony Botts.

In the Know is a monthly partnership between LP Gas magazine and Propane Resources. Our focus this month is on supply logistics, addressed by supply expert Tony Botts.

Q: Supply availability is a major issue going into this winter, but there is also concern surrounding the logistics of obtaining supply, especially by rail. What can propane retailers do to combat logistics issues they might face during the heating season?

A: The traditional build season for propane is behind us and we are turning our focus to the heating season.

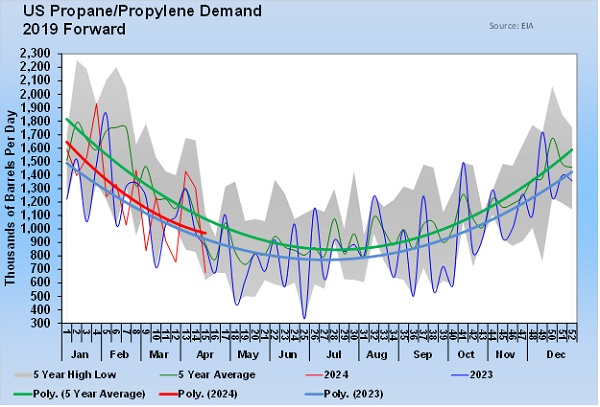

Winter brings questions of demand, adequate inventories and supply disruptions. Domestic demand projections have yet to be determined, as multiple forecast models and predictions appear to paint a wide range of seasonal weather scenarios. Inventories are what they are; we are nearly 25 percent behind last year’s inventory levels, with export capacity well above 1 million barrels per day (bpd).

The first two variables will determine the severity, or lack, of supply issues or disruptions. Those worries tend to revolve around fears of allocation, pipeline accessibility and product availability at both primary and secondary supply points.

Drastic changes to pipeline infrastructure over the last few years have forced many retailers to adjust their supply strategy. Some have transitioned away from pipeline terminals to securing allocation at railcar terminals. Unfortunately, rail executives have changed the supply landscape for many retailers and suppliers.

CSX Transportation declared that numerous hump yards, or switch yards, would either be shut down or transitioned to perform different duties. The move is part of an effort to improve delivery time and remove delays in the transportation process.

One industry expert says this could lead to two scenarios in some areas: too much gas or not enough gas. In the event of oversupply, this could take precious gallons or loads of propane away from regions with greater needs for the product. Too little gas and retailers could be scrambling to locate loads far outside their supply territory.

This adds another issue to retailers’ plates. The scramble for transport loads could create a backup for transport trucks securing loads of gas in a timely manner, again, costing precious time and margins.

The obvious solution is compiling a diverse range of supply points with allocation spread out. Use a combination of rail terminals, pipeline access or private storage terminals to cover your supply inventory. It may also be beneficial to layer in additional gallons through hedging or other physical risk management options.

Understanding what your company needs to operate over a 30- or 60-day period is crucial. Know the volume of gallons you require to get your customers through each month of the demand season under normal conditions.

When supply becomes tight, your main loading point may not have the product you need. Your secondary supply points will greatly impact your margins, though it may cost 30 cents per gallon more than your primary supply point.

Every retailer needs to be prepared to address the costs of going outside its normal supply area. Know what it costs you to haul from multiple supply points. If you don’t operate your own transports, have that conversation with your transport representatives. Additional freight costs should not mean you have to sacrifice your entire margin.

If you sell fixed-price contracts to your customers, do you have a force majeure clause to add increased freight costs from secondary supply points?

This past winter saw a drastic change in the way the industry views exports and domestic supply. We saw exports routinely surpass the 1-million-bpd mark and the effect they had on dwindling supply during the first quarter.

Retailers may have caught a break in that department this winter as news the Mariner East 2 pipeline may not go online until the second quarter of 2018 begins to emerge. This pipeline runs from the Marcellus and Utica shales to Marcus Hook, Pennsylvania, with the intention of bolstering export capacities. However, the 275,000-bpd pipeline is experiencing numerous legal battles, which could ultimately delay its anticipated operational start date. Pair this news with the less-than-expected crop drying expectations, and the Midwest may have avoided two crucial variables on the supply spectrum.

Supply concerns can keep retail operators up for many nights. Tight supply markets generally lead to higher prices. Current prices at Mont Belvieu are already in the low to mid 90-cent range. Any retailer who has been in the industry for at least four or five years knows that prices can go much higher – and do so in a hurry.

Remember, protect your margins and protect your customers by spreading out your supply allocation. Build relationships with some secondary supply points and know what your business needs to get through a tight squeeze.

The hit HBO series “Game of Thrones” was on to something with its highly popular tag line: “Winter is coming.”

Winter is definitely coming, and the answers to our supply concerns and questions will soon arrive with it.

Tony Botts is a supply expert at Propane Resources. He can be reached at 913-262-0628 or tony@propaneresources.com.