Rust never sleeps

There are some things in life that are as inevitable as the rising and setting sun. Death and taxes are the leading candidates and not far behind these twin powers is rust, which never sleeps.

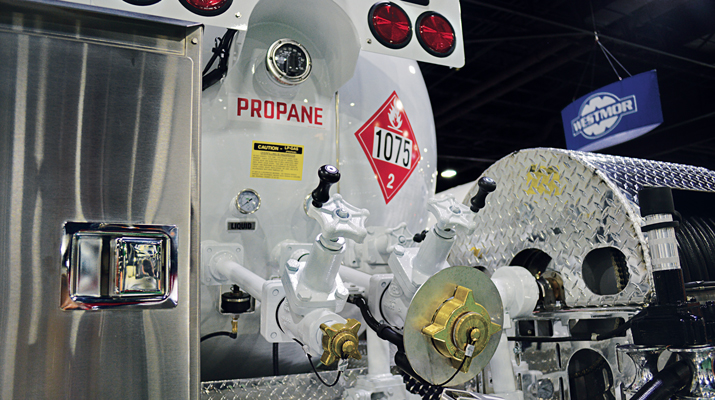

As propane marketers, the presence of rust and the risks it brings to your operations have to be continually monitored.

John McCoy |

There are many opportunities to track the presence of rust, or corrosion. Looking for rust in your inventory and at customer facilities is a proactive safety practice that can help you avoid catastrophic accidents. It can also be the basis for developing new service business and customer goodwill.

Whenever a cylinder is refilled and a visual inspection is conducted before refilling there is a check for rust, gouges and dents.

The inspection should always include checking the cylinder’s base, as this is often where rust first appears on cylinders. This is likely because the base comes in contact with moist and/or caustic surfaces on a more frequent basis than the rest of the tank. The base is also hidden from visual observation during normal use, so rust isn’t easily spotted.

When at customer locations, always look at the entire surface of your tanks to be sure they do not appear to have excess corrosion. Buried tanks pose a particular problem since they are not observable.

However, all tanks that are buried should be buried with corrosion protection, which should include cathodic protection. NFPA 54 and 58 discuss the need for corrosion protection so be familiar with those requirements and always follow them.

Watch out, though. The presence of corrosion protection is not a guarantee that the buried tank will never corrode to the point where it’s no longer safe.

For instance, tanks that are buried with corrosion protection can be nicked in a small area on their surface during the burying process or later by movement of something in the subsurface. This may develop a holiday – a gap in the protective coating of the buried tank – on the tank surface.

When this occurs, the low electric current that creates corrosion in underground tanks is focused on the holiday in the tank and the rate of corrosion at that point is accelerated. If the tank had no corrosion protection the corrosion would have been spread over the entire surface of the tank but at a much lower rate.

As a result, the process of burying tanks, lines and piping connections should be done with care.

Simply because a tank, line or connection was buried with corrosion protection does not mean that the risk of a leak from corrosion can be ignored.

When there is an unusual increase in gas consumption or a customer complains of a gas leak, you might consider the possibility that corrosion may have compromised an underground line, tank or connection.

If you are in the business of service work you might offer an inspection to your customer base, for an annual fee, to monitor the gas system your tanks connect into.

If you do this you should make clear that your inspection only confirms that there is no leak in the system at the time you conduct your inspection. It is never a guarantee that a leak from corrosion in the future is eliminated.

John V. McCoy is the president of McCoy & Hofbauer, S.C. and specializes in the representation of propane companies. He can be reached at jmccoy@mh-law.us or 800-599-8300.