Safety oversight rests with individual company leadership

Safety oversight is a critical component to safety success.

There are at least three types of oversight: external regulatory oversight, internal company oversight and employee decision-making oversights made in the field.

The recent explosion at a fertilizer plant in West, Texas, gives us a great example of the importance of safety oversight. This tragedy involved significant injury, death and destruction involving the public, employees and emergency personnel. In the wake of such tragedy, you can bet that past oversight inspections will be reviewed and new regulations are sure to follow.

You don’t have to experience a tragedy to prevent one. We can learn from past mistakes in related industries.

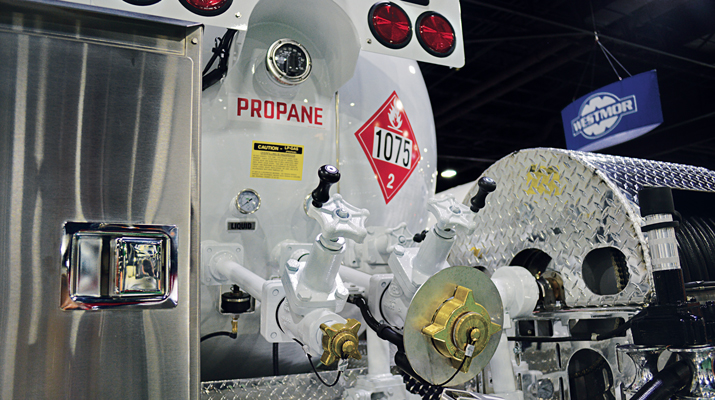

While propane plants and anhydrous ammonia plants have similar exposures and compliance issues, the toxic nature of anhydrous ammonia can complicate concerns when an accident occurs. In addition, many propane marketers in rural areas also handle anhydrous ammonia. In parts of the country, propane systems have been contaminated. Exposure to anhydrous ammonia can be a serious safety concern that deserves your internal oversight.

That said, let’s talk about safety oversight.

An agency having jurisdiction (AHJ), such as a fire department, department of transportation or the Occupational Safety and Health Administration, may be charged with oversight issues, such as inspections and audits for compliance. Unfortunately with AHJs, not all parts of our country truly inspect what they expect when it comes to compliance of existing systems. In some areas, external oversight generally only happens after an accident occurs.

New facilities are initially inspected prior to operation, but there is rarely a return visit once that is done. In addition, AHJs for local oversight, such as city inspectors, are sometimes poorly trained and in some cases have ignorantly signed off on unsafe systems.

For example, a poor domestic installation that is not compliant with code may pass a cursory inspection by a local contractor or builder and miss exposures to carbon monoxide or some other error or leak. After an accident, the inspector may lose his job, but an expert witness could target your company in a legal claim.

Unfortunately, that inspector may get a job doing the same thing in another city, town or state. Even worse, the same expert witness will get paid to expose oversight over and over again.

This is where internal oversight within your company can and will prevent accidents. Never assume when it comes to documenting your compliance with regard to service, installation or delivery. You may catch a mistake made by a contractor, overlooked by an inspector or an unintended oversight by one of your employees. Never apologize for inspecting what you expect.

While this responsibility usually falls on safety directors or local managers, true oversight responsibility rests with individual company leadership. A company reflects attitude of senior management when it comes to safety. These leaders sign the checks, set the tone and get involved – or they look the other way. In fact, management will be the first called by a plaintiff’s attorney to testify about internal oversight practices. At your next safety meeting, I recommend a discussion on oversight:

■ How is the local situation with regard to external oversight initiated by AHJs in your area?

■ Can you trust they will actively do their job to review your compliance?

■ Do you have an internal company system to check assurances from contractors and AHJs that they did their job competently?

■ When it comes to internal oversight, do you inspect what you expect with regard to customer, employee and plant safety?

■ Is employee oversight a problem where stuff falls through the cracks, creating an accident waiting to happen?

When we make the time to discuss, evaluate and appreciate safety oversight as a major component to preventing accidents, we take control of our own environment and pave the ways for profitable results.

Jay Johnston (www.thesafetyleader.com) is an independent insurance agent, business consultant and safety leadership coach and speaker. He designs and implements risk management programs. Jay can be reached at 952-935-5350 or jay@thesafetyleader.com.