Training autogas technicians

Expo attendees inspect the bi-fuel Prius, one of the NAFTC’s training tools. Photos courtesy of the National Alternative Fuels Training Consortium

The National Alternative Fuels Training Consortium (NAFTC), with support from the Propane Education & Research Council (PERC), held a three-day propane autogas training expo in Sanford, Florida, giving auto technicians a chance to learn how to service autogas-fueled vehicles.

Though autogas is growing in popularity, the number of auto mechanics is in decline, meaning there are fewer people to service the vehicles. According to Stuart Flatow, vice president of safety and training at PERC, in order for the autogas market to be successful, there must be enough skilled technicians who can troubleshoot, diagnose and maintain autogas systems.

If technical colleges can turn out more young mechanics who are equipped to service propane autogas vehicles, the fuel may look more appealing to those looking to invest, thereby giving both industries a boost.

“Events such as the PERC-funded NAFTC Expo and technician training classes provide an opportunity for networking amongst several autogas stakeholders and allowed representatives from technical automotive schools, aftermarket organizations and propane professionals to work together to identify needs and solve issues that will help expand the autogas market,” Flatow says.

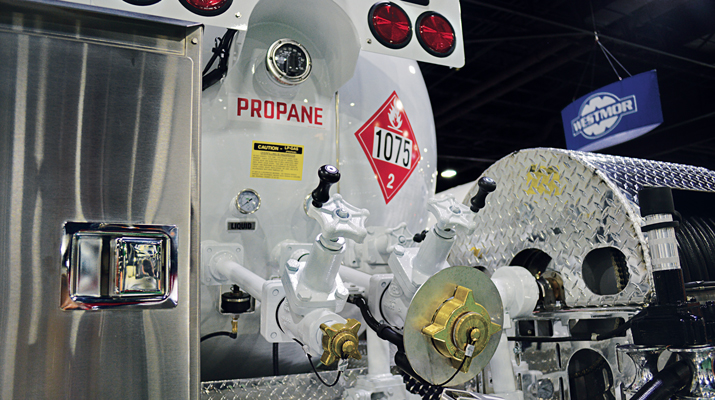

The event gave the trainers a chance to see and learn how to operate the propane autogas training tools in NAFTC’s arsenal. These tools give technicians the opportunity to work hands-on with alternative fuel vehicles and can be used in the classroom to train the next generation of auto mechanics.

“We need skilled trainers to educate people on why and how to troubleshoot; that’s what this course is about,” Flatow says. “It’s troubleshooting. When maintaining systems, you have to think outside of the box.”

Get ’em while they’re young

The question remains, however, how to attract young people to these types of jobs. The average age of an auto mechanic is 43, and many of the individuals entering technical or community colleges to pursue this career are older, according to Patrick English, an instructor at Ferris State University.

One way is to offer dual credit in high school, giving students an opportunity to work toward their careers while they are still receiving their secondary education. This also provides flexibility for students who may not enjoy a traditional classroom experience.

It’s also important to change the conversation surrounding these jobs. Though college is a common option for students, not everyone has a career plan and can follow through with it, especially when they’re in high school, Flatow says.

Another obstacle preventing young people from entering this workforce is the type of support they receive while in secondary school. Guidance counselors, and even some parents, often have the mind-set that a four-year degree is superior, English says.

One solution is to invite guidance counselors to the technical schools and give them tours of the facilities, so they can learn about the opportunities that exist for these young people.

Schools need to change, Flatow says. He is optimistic that in the next four to five years there will be shifts in the way young people approach their careers. Colleges and universities will become too expensive, according to Flatow, and young people will start to look beyond college for what makes them happy.

Part of the responsibility for attracting workers to these industries falls on the employers. Managers should be trained on how to speak to younger generations and understand what they are looking for in a career.

“People need jobs, but if someone makes enough money to sustain themself, they’re happy with the perks,” Flatow notes. “Employers need to understand that.”

Blended is better

As workforces age, so do their instructors and trainers. Both the propane industry and the auto technician industry are faced with this difficulty.

According to Flatow, it’s important to train instructors on how to teach younger generations, which means incorporating blended learning into curriculums.

“Millennials want to learn at their own pace,” Flatow says. “They want it to be hands-on and collaborative. They don’t want to sit in a classroom and be lectured at.”

This is where NAFTC’s tools become important. They allow trainers to teach in the classroom and show their students hands-on what the work is like.

“ATech is one of the global leaders in building the best training tools out there,” says Micheal Smyth, acting director of NAFTC. “They approached us and said, ‘We want to develop alternative fuel training devices.'”

Hands-on training engages the younger workforce and allows students to see that they are capable of doing the work, according to Laura Lyons, president of ATech.

“When we first started this class there wasn’t near as much hands on,” Smyth says. “This wasn’t originally written into our standard courses. We found out quickly they [technicians] are looking for different training. They probably already have some experience in the basics of autogas, so they’re looking for diagnostic and repair standpoint, so we had to build that into the coursework.”

Using their hands helps students engage with the work and gives them the opportunity to learn by doing, Lyons and English say.

The training equipment ranges from the simple to the complex. An electrical trainer, a relatively simple device, teaches students how to connect circuits and read a meter, something used in almost every mechanical application. The simpler trainer breaks down information, allowing for early successes, which increase engagement, according to English.

The more complex trainers include a bi-fuel engine trainer and a Toyota Prius equipped with a bi-fuel engine, in addition to the traditional battery of the hybrid. These trainers give students opportunities to learn how to maintain these types of engines and troubleshoot problems that may arise.

The type of blended learning opportunities these tools afford lowers the barriers to training and allows trainers to teach efficiently while ensuring students understand the materials.

UPCOMING TRAINING SESSIONS

UPCOMING TRAINING SESSIONS

The National Alternative Fuels Training Consortium, with the support of the Propane Education & Research Council, plans to hold more expos at different sites around the U.S. The next two training sessions are:

Iowa

Iowa Central Community College

(East Campus)

Fort Dodge

June 12-14

Texas

Universal Technical Institute

Irving, Texas

July 31-Aug. 2