Addressing cavitation, other pump challenges

Cavitation and net positive suction head (NPSH) issues are often misunderstood common detriments to effective pump operation.

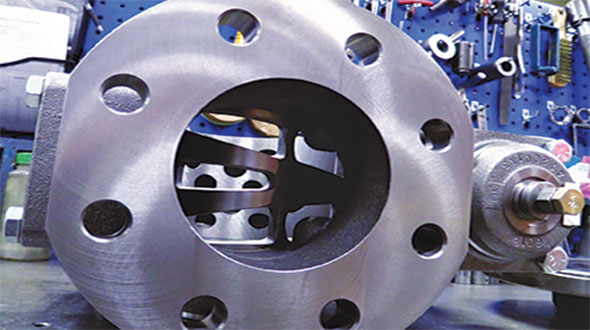

Eliminate cavitation by eliminating vapor. Photo courtesy of Blackmer

Entire plant systems can fail unexpectedly as a result of a mechanical-seal or pump-component failure. Plant operators may observe: “It sounds like gravel is being pumped through our pipe” or “The pipe is shaking” or even “The pump components have dissolved into nothing.” When such failures are assessed further, operators often conclude that cavitation and NPSH are ultimately to blame for the seal and pump failure. As a result, all process engineers know that pump-suction design is what’s most critical to ensuring reliable operation of any piping system.

Although NPSH sometimes seems confusing, it can be simplified when viewed as a part of a monetary budget. In the same way that a company may default if withdrawals exceed deposits, a pump may be destroyed if it withdraws more NPSH than the NPSH budget provided by the piping system. In short, a pump should not withdraw more NPSH than what is provided by the piping system. If the pump has a surplus of NPSH, then vapor is not formed and there is no potential for cavitation. Conversely, if the system has an NPSH deficit where the pump withdraws more than what the system provides, then vapor will form and destructive cavitation will occur.

Cavitation is the implosion of vapor bubbles within the pump’s pressure stages and occurs only if vapor exists. Vapor can form upstream of the pump, within the pump or both. Pump operators know cavitation as noisy and destructive. When vapor implodes, the liquid walls collapse and produce shock waves of incredible force that cause destruction upon impact.

These shock waves can cause excessive vibration and noise within the pump, which can result in significant damage to internal components. This cavitation damage will set off a chain reaction of negative effects that can include loss of operational efficiency, elevated maintenance and part-replacement costs, pump downtime and, in the worst-case scenario, total pump failure.

Cavitation can affect the performance of all pumps. This article illustrates how a specific type of pump technology – positive displacement sliding vane – incorporates a revolutionary technology known as the cavitation suppression liner, which mitigates and even eliminates the harmful effects of cavitation.

The challenge

Plant operators and process engineers often focus attention on the pump’s NPSH required. After all, cavitating can be avoided if a pump requires less NPSH than the system’s NPSH budget.

Unfortunately, this perspective misses that vapor is often formed upstream of the pump. This is especially true when transferring fluids with high vapor pressures. The vapor pressure of these liquids is greater than any NPSH provided. In other words, these applications operate at a deficit from the start: The liquid demands more than what the system could ever provide.

Even in low-vapor-pressure liquids, the physical system layout may require poor conditions such that the NPSH budget provided by the system is so low that no pump could operate within the allowance.

An NPSH deficit is created in either of the above scenarios. A portion of the fluid transitions to vapor and creates a multi-phase or “boiling fluid.” The vapor concentration and size increases as the level of NPSH deficit increases. However, regardless of the vapor concentration or size, the vapor will implode during a pump’s pressure stage, causing violent reactions that are the root cause of cavitation’s destruction.

There are a number of pumping setup conditions that can result in a dangerous NPSH scenario, including: excessive suction-lift requirements; long piping runs; flow restrictions at the inlet, such as the presence of a piping elbow; a clogged strainer; partially closed valves that can restrict flow; and unnecessarily high flow velocities caused by undersized piping.

An operator hears destructive cavitation as elevated noise levels during system operation. Vapor-bubble implosions within the pump will make it sound as if the pump is filled with bits of gravel.

If these cavitation-causing conditions are present and allowed to persist, damage to the pump and its components is almost certain to occur. Dynamic components are especially sensitive to cavitation. Specifically, the pump’s mechanical-seal faces will briefly separate as the implosions occur. The shock-wave pulsations create a condition known as “chattering,” which leads to premature wear and failure of mechanical seals. Additional failure can be expected in other wetted parts.

While we know that cavitation can be minimized by optimal system design, system engineers should familiarize themselves with a technology that is well suited for continuous cavitation service. Such technology would minimize or eliminate the destructive effects of cavitation and provide better performance and long pump life.

The solution

The key to eliminating pump cavitation and its harmful side effects is to eliminate vapor.

Alternately, system engineers can set operational parameters in such a way that the NPSHa (budget) will always meet the NPSHr (consumption). However, most systems require a solution designed for the worst conditions.

The cavitation suppression liner defeats cavitation through a design that defuses or mutes destruction before vapor implodes. This feature creates internal recirculation jets that break apart vapor bubbles before implosion. While the vapor levels are not reduced, the size of each vapor bubble becomes a fraction of what it would have been, yielding smaller implosion reactions.

The cavitation suppression liner also allows a controlled amount of fluid at discharge pressure to bleed back toward the suction of the pump. This breaks the larger vapor bubbles apart into smaller vapor bubbles before they have a chance to implode. The net result is less noise, less vibration and less wear.

Unchecked cavitation will harm pumps in many ways, among them excessive wear of internal components, breakdowns, product leakage and compromised operation.

Geoff VanLeeuwen is a product manager for Blackmer and PSG.