Beating the electric heat pump

With hydronic heating, tankless water heater installations will also serve as a backup space-heating source in homes. Photo courtesy of the Propane Education & Research Council

A pilot project being conducted by multiple industry entities that links propane tankless hot water heaters with electrically powered heat pumps could bring better winter comfort and electric-bill savings to customers while increasing propane consumption.

Called “hydronic heating,” the system under study involves plumbing a hot water heater into a water coil assembly installed inside a heat pump’s air handler apparatus – thus replacing the heat pump’s inefficient auxiliary “emergency heat strip” that activates during cold snaps.

“If the product concept is economically feasible, it can provide an additional gallon load to propane marketers,” says Greg Kerr, director of research and development at the Propane Education & Research Council (PERC), which has contributed $25,000 to help fund the pilot program currently taking place in North Carolina.

“The quality of heat from this concept is much better than electric-strip heat, which typically is the second-stage heat for heat pumps,” Kerr adds.

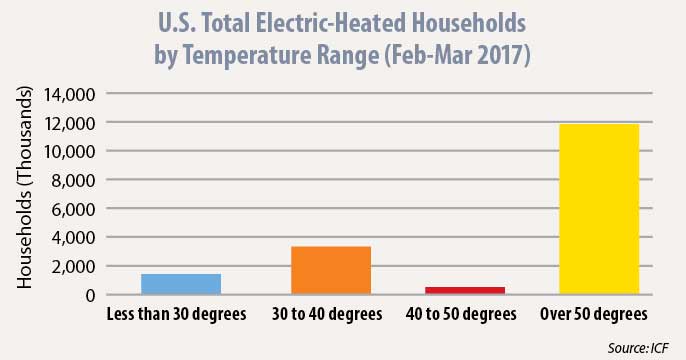

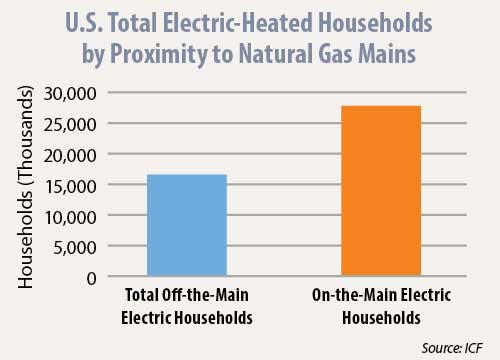

Prime sales prospects include all-electric homes off the natural gas grid in climates with winter temperatures in the 30- to 40-degree range. Should the pilot program prove to be practical, and if you can sell homeowners on the pluses of a propane tankless hot water heater, they may also opt for the heat pump tie-in technology.

The propane industry could target existing homes and installations in new construction, multifamily residences, manufactured houses and mobile homes. Photo: iStock.com/Marje

“We’ve been going down this path of having a response to the electric heat pump, which has cleaned our clock over the years,” notes Randy Doyle, CFO at Blossman Gas, which is among the leaders of the project.

“We’re developing a solution, a hydronic product – basically heat from a tankless water heater. We use it instead of the electric heat strip kicking on when temperatures drop below 40 degrees. The hydronic would kick in, and it enriches the value of the tankless water heater, now used as a backup heat source for the heat pump. It’s higher-quality, lower-cost heat for the consumer,” Doyle explains. “We’re very excited about the possibility of this coming to market.”

Nine experimental installations are in place, with two remaining to complete. All will be monitored during the upcoming heating season, according to Armistead Mauck, vice president and co-owner of Cherry Energy, one of the project leaders. Tangible results are expected by the spring of 2018.

“This is a hot button for propane marketers because it addresses the residential business,” Doyle says. “Propane as a hydronic heat source is extremely competitive for the homeowner.”

Bear in mind that the term “hydronic” can also be applied in a differing context to describe liquid-filled pipes installed under floors to supply radiant heating. As the propane industry’s endeavor moves forward, a more-suitable moniker for the water heater/heat pump array is likely to be contemplated.

Plug and play

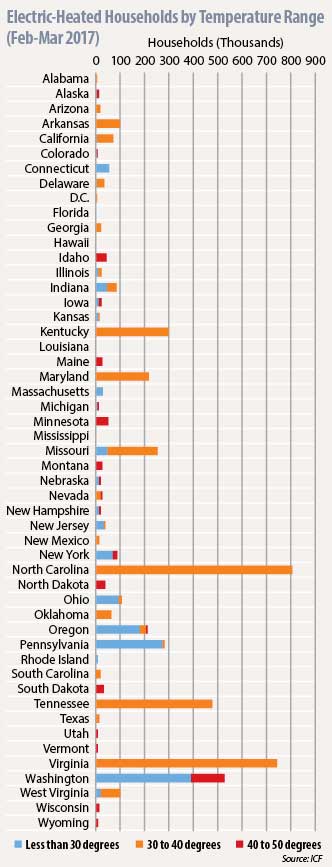

State-by-state household data from ICF gives the propane industry insight into potential new customers. Click to enlarge.

“We’re doing the test pilot programs so we can understand it so we can sell it,” says John Jessup, executive director of the North Carolina Propane Gas Association (NCPGA). “The pilot will determine how we convey the results to our members. We may set up classes where we invite retailers to come for training on this system.

“We have to do some crazy things to engineer this,” Jessup adds. “Your water heater could be in the garage and the heat pump could be on the other side of the house. We’re trying to make it as easy as possible – a one-button system.”

Having plug-and-play installation at customer locations is an ideal endeavor for the propane industry, Mauck adds.

“Can we package this thing up so the customer doesn’t have to peek through the door (of the utility room) and watch the sausage being made?” he says. At present “you have to grab a whole bunch of things off a shelf” to piece together the related components. “We want you to reach up to a shelf and take down a box.”

Retrofitting existing homes and installations in new construction, multifamily residences, manufactured houses and mobile homes are all potentially lucrative avenues for adaptation.

“For the manufactured home, we see this as a natural fit,” Doyle says.

“Right now, with the space requirements in a mobile home, the tankless is a perfect source. It opens us up into that market,” he says. “If you look at the numbers over the last 15 to 20 years, propane has lost 30 to 35 percent the number of mobile homes and manufactured homes on propane. It’s a market propane once dominated that we’re losing.”

According to estimates from ICF, in North Carolina alone there are more than 1.3 million all-electric homes located off the natural gas mains, including more than 800,000 where winter temperatures fall into the 30- to 40-degree range, heightening propane’s sales prospects per tankless hot water heaters while boosting heat pump performance and savings.

Kentucky, Missouri, Tennessee and Virginia, for example, are other states with high numbers of electrically heated homes with winter temperatures averaging in the 30- to 40-degree range.

“Residential has always been our bread and butter, and for years we’ve been losing ground to the heat pump,” Jessup says. “Some 60 percent of gallons in North Carolina is residential,” covering LP gas stoves, fireplace logs and the like. “We’ve been told we don’t need HVAC or plumbing certification to do the retrofits” regarding water heater/heat pump linkage in existing homes.

“We’re working so it’s cost-competitive,” Doyle says. “We understand that we have to offer rebates to the consumer and make it competitive. Ultimately what we do has to be price-competitive to the consumer.”

Twice the load

This technology has the potential to be a hot seller once the various elements of the pilot program are analyzed and addressed along with identifying and establishing pricing parameters.

The hydronic system has two main components: the tankless hot water heater and the hot water coil. They currently are purchased separately. In this picture, the hot water heater is from Rinnai and the hot water coil is from First Co. Photo courtesy of Armistead Mauck.

“That’s what we’re trying to figure out,” says Joe Holliday, senior director of business and product development at Rinnai America Corp., which manufactures propane-powered tankless hot water heaters and is serving as the hydronic system’s integrator.

“It’s getting twice the load because you’re not just using it for water heating, but you’re also using it for space heating. It’s a way to grow your gas load,” he says.

In pondering a tankless hot water heater installation job, you want to “size the house for the hot water needs,” taking into account the number of bathrooms equipped with showers and/or bathtubs, plus dishwashers and washing machines, and how many people are living in the residence.

“If the air handler (containing the blower, hot water coil and its circulation pump) comes on, we’re still going to power the showers – domestic hot water gets priority,” Holliday says. “We push warm water through that water coil in the air handler, and it warms the air before it’s distributed throughout the house. You’re getting your gas heating and water with one heat source, one engine. The hot water heater drives that other appliance.”

Several companies produce water coils suitable for the application; First Co. of Dallas is providing the units used in the pilot program.

“We’re taking the equivalent of a car radiator and putting it in the ductwork,” Mauck says.

Ruminating on the prevalence of stand-alone heat pumps, he points out that “it’s a great solution, but it’s eating our lunch in this industry.”

“That’s exactly right,” agrees Doyle. “This also sweetens the application for the tankless water heater, which now could be used as supplemental heat to the electric heat pump, rather than when it gets cold the electric heat strip turns on. The [electric heat strip] is a more expensive source of heat and, second, it’s not as good of a quality of heat.”

Reflecting on the hydronic application, “the people who have it love it” Jessup reports, “and it’s a warmer heat than the heat pump.”

Rinnai, with its tankless water heater technology, is serving as the hydronic system’s integrator. Photo courtesy of the Propane Education & Research Council

Doyle calls it more of a “moist heat.”

The solution can also provide medical benefits for people with skin conditions, Mauck says. He contends that heat pump users are wont to complain “there are certain days in the year when I just want to throw this thing in the trash can” because the degree of desired heat just isn’t there. Customers experiencing the hydronic option are likely to conclude: “I like this heat so much I want a dual-fuel system,” he adds.

“We’re working with Rinnai to streamline all that,” Doyle says. “We’re bringing disjointed pieces together. The pilot teaches us about the application so we know how to market it.”

“They see it as a tool for marketers to sell more of their tankless hot water heaters,” Mauck says, noting that Rinnai’s customers “like the concept of instant hot water” being provided via an appliance that takes up less space than a traditional hot water heater.

A collaborated effort

Unlike an electric, natural gas or propane furnace, a heat pump doesn’t rely on a fuel source to generate heat. Instead it utilizes electricity and refrigerant to transfer heat contained within the air outdoors into the structure, like a reverse air conditioner; in the summer, a heat pump can provide interior cooling.

“At 50 degrees, the electric heat pump is a good source of heat,” Doyle says. “Once it gets cold, the electric heat pump is beyond capacity and the system relies on the backup source heat, which is where the heat strip comes in.”

With the hydronic aspect, “what this would do is replace the electric heat strip,” he says. “The system has gotten below 40 degrees outside and is calling for more heat. Rather than the electric heat strip kicking in, the hydronic would kick in and the heat source would come from hot water.”

Doyle began pursuing the concept about two years ago, and planning began in earnest last August.

“Blossman Gas came to us, and they wanted to run this test in North Carolina,” Holliday recounts, and the industry cooperatively rallied to make the idea happen.

Electric-heated homes located off the natural gas mains serve as the best sales prospects for the hydronic application.

North Carolina propane marketers involved in the project included Mauck at Cherry Energy, Scott Prewitt of Blossman Gas and Donnie Bullock of Williams Energy; key consultations from Mike Sloan of ICF; Tucker Perkins and Greg Kerr from PERC; Jessup at the NCPGA; and even the head of the North Carolina Plumbers and Contractors Association.

Blossman Gas and Cherry Energy have long been industry stalwarts interested in exploring innovations. Jointly venturing in the hydronic research realm is yet another significant industry development.

Established as Cherry Oil in Kinston, North Carolina, by Guy T. Cherry in 1928, the company remains a family business, growing to include a variety of fuels with vast applications.

Founded in 1951 with one truck in Ocean Springs, Mississippi, by E.W. “Woody” Blossman, who had everyone on 24-hour call with the philosophy of “Don’t leave ’em cold,” Blossman Gas is the largest family-owned independent propane business in the United States. It has some 70 outlets throughout the Southeastern and mid-Atlantic regions, ranked as the seventh-largest American propane dealer.

“The project was a collaborated effort. It really captures the spirit of everyone working together,” says Doyle, crediting Mauck for coming up with deep-thinking breakthroughs during a crucial brainstorming session. “I saw Armistead and he had this ‘ah-ha’ look on his face.”