Composite cylinders poised to make an impact on the exchange market

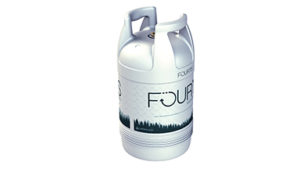

According to Kundhi, customers like that they can see the fuel level in the cylinder through the open panel on the side. Photo By Joe McCarthy.

If you mention propane to the average American, the scene of a 20-pound steel cylinder hooked to a backyard grill instantly comes to their mind. It is undoubtedly one of the most classic uses of the fuel. However, composite cylinders stand on the fringe of the cylinder exchange market and are poised to change that backyard scene in the years to come.

A composite cylinder is the combination of fiberglass and a resin, explains Craig Bruch, quality manager at Hexagon Ragasco North America, the parent company to Viking Cylinders, which produces a line of composite propane cylinders.

Proponents of composite cylinders like several of their features. The cylinders do not corrode; they weigh less and allow for simpler maintenance while still serving end users with the classic use of propane.

Tarun Kundhi, who works in business development for Viking Cylinders, says composite cylinders have benefits for both the propane marketer and the end user.

“On the consumer side, it is lightweight and has a stable base,” Kundhi explains. “They are easy to transport.”

Because composite cylinders are rust resistant, marketers save on cylinder refurbishment costs, and end users find the cylinders more attractive, Kundhi says.

Viking’s Tarun Kundhi and Criag Bruch. Photo by Joe McCarthy

“For a propane company that needs to sand and refurbish their tanks on a regular basis, they won’t need to do that with a composite cylinder,” says Bruch. “You wash it when it gets dirty, but it is not going to corrode and it is not going to deteriorate.”

Since they don’t corrode, composite cylinders also stand up to salty air and perform well in marine applications, says Mark Komlosi, director of LPG products at Worthington Industries, which also offers a line of composite cylinders.

“Another big advantage, primarily for consumers, is you can see how much gas is in our tank,” Kundhi adds. “So, they really find that as the No. 1 benefit.”

Eric Smolenski, general manager for industrial products at Worthington Industries, and Komlosi note the higher production costs for composite cylinders, which can be two to three times as much as steel cylinders, creating challenges when working with the North American market.

In fact, propane retailers who have not adopted composite cylinders in their operations cited cost as the main reason, according to an LP Gas magazine survey about the cylinder exchange market.

Exploring the market

Worthington Industries manufactures steel and aluminum cylinders, and acquired Amtrol-Alfa, a European manufacturer of lightweight steel and composite cylinders, in June 2017.

Komlosi says the acquisition was a good way for the company to expand its global footprint and offerings. Worthington Industries is currently exploring the composite cylinder’s place in the North American propane market.

Amtrol-Alfa added low-pressure composites to its portfolio in 2005 when the demand for a lighter, more user-friendly cylinder for domestic use was growing in the European and Middle Eastern markets, Smolenski explains.

Photo courtesy of Worthington Industries.

“In North America, we’re in exploration mode,” he says. “Our team is speaking with end users – both those who refill their own cylinder and exchange – as well as propane marketers and retailers. We’re interested in understanding needs, pain points and creating the ideal experience for specific audiences.”

Komlosi notes challenges in working with the current cylinder exchange infrastructure in North America.

“The North American customers have adapted to using a steel cylinder, and their infrastructure is based around that steel cylinder,” Komlosi says.

“Compatibility is not only grills but exchange markets where they have cages and trucks specifically set up for a [steel] 20-pound propane cylinder. Now you are introducing a new cylinder, which isn’t really a drop in replacement. It does have some unique characteristics, but there are some challenges, as far as people adapting to the new cylinder.”

According to Komlosi, Worthington Industries is showcasing the composite cylinders to gauge interest levels in the United States.

The state of the cylinder exchange market, Kundhi says, depends on the end-user level.

“Indications are that when a consumer understands the benefits they get in a composite cylinder, up to 30 percent are willing to make the switch,” he says. “The challenge for us is, how do we educate consumers about the cylinder.”

Seven propane retailers across the country are currently using Viking Cylinders in their exchange programs.

“Our customers build an exchange brand around our cylinders,” Kundhi says. “That is what the consumer really needs to be educated on.”