Enhancing truck operator safety

Safety is as critical as ever in the propane industry. Therefore, manufacturers are offering a variety of technology advancements, which will boost truck operators’ safety for years to come. Here’s a look at some of the product developments for the propane market.

Camera system among enhancements

Columbus, Wisconsin-based Fisk Tank Carrier has revealed several new safety items and advancements at propane trade shows this year.

One advancement is a new camera system that features four cameras, which can be used on each side of an operator’s truck. As a result, an operator can overcome any visibility challenges they may have previously experienced while positioning their trucks. After all, they’ll have visuals of every side of their truck all at once, enabling them to see any obstacles throughout the positioning process.

“This system will help prevent truck accidents, costly damage and injuries,” Nathan Roberts, owner of Fisk Tank Carrier, says. “At operators’ plants, the 360-degree camera views can also be seen on a master program, allowing propane retailers to acquire recorded footage if accidents occur, while helping them evaluate their jobsite processes as well.”

The new camera system provides drivers with improved visibility around their trucks. (Photo courtesy of Fisk Tank Carrier)

At the same time, the manufacturer has added a sonar system, via motion sensors, to its trucks’ rear bumpers. Consequently, operators will hear a beeping sound whenever they’re near an object or person; this sound will increase in speed as they get closer.

“The sensors will help operators overcome the challenges of maneuvering their trucks into tight positions,” Roberts says. “Not only do the sound signals quicken as operators are closer and closer to objects and people, but they’ll also increase in volume to ensure operators hear them and reduce any likelihood of accidents.”

In addition, Fisk Tank Carrier has added ground effect lighting underneath its trucks, resulting in a halo of light around each truck, which will benefit operators who work in low-light conditions. By seeing the ground they’re working on during their deliveries, operators will decrease any possible accidents and injuries.

The new rear bumper sonar systems will alert drivers of objects and people behind the truck. (Photo courtesy of Fisk Tank Carrier)

Finally, Fisk Tank Carrier is providing propane marketers a virtual reality training system as well. Created to help propane marketers train their employees about new cranes’ features, the system will ensure that every crane operator can be trained at their respective employer’s plant. Therefore, they’ll have consistent training offerings, leading to more dependable crane operation and enhanced safety.

“With each of these advancements, propane marketers’ and truck operators’ on-the-job safety will be less of a concern than it previously was,” Roberts emphasizes. “They’ll be able to focus more on their job tasks, rather than any potential injuries associated with those tasks.”

Gaining “total control” of the crane

During the 2024 Southeastern Convention & International Propane Expo, H&H Sales Co. Inc., a custom truck body and equipment provider in Huntertown, Indiana, displayed Stellar Industries’ 7630 telescopic crane.

Offering operators a 7,500-pound capacity, the crane also has 30 ft. of reach. Additionally, it features the CDTpro control system, which has range finder technology. This technology allows operators to operate the crane with a remote controller, thereby remaining clear of any load paths.

“With the Stellar CDTpro, operators have total control, a critical advantage whenever they’re handling propane tanks,” says Tyler Havens, product manager at Stellar Industries.

By acquiring real-time feedback – concerning the crane’s load capacity, the amount of weight that’s on the crane at a certain time and the total weight capacity that still remains – operators can make informed decisions within a matter of seconds. They’ll also receive warnings on their remote controller whenever the crane is overloaded or approaches its maximum capacity.

New ground effect lighting illuminates beneath and around the truck for operators working in low-light conditions. (Photo courtesy of Fisk Tank Carrier)

If operators must increase the crane’s weight capacity, they can do so via CDTpro’s Boost Mode. As a result of this technology, operators can simply hit their remote controller’s button and receive an 18 percent uptick in crane capacity for 30 seconds. While doing so, they’ll never have to worry about using a larger crane or moving their truck either.

User-friendly and durable, the CDTpro also provides water resistance and dust protection, along with a backlit display that operators can effortlessly view, regardless of where they’re utilizing it. Moreover, since the offering has range finder technology, operators can create their lift plans without having to unstow their crane. Hence, they’ll have ample time to determine exactly how much the crane can lift, prior to moving objects with it.

“The CDTpro’s technological advancements help operators avoid unnecessary, costly mistakes on the job,” Havens says. “They have all the power – directly in their fingertips – as they move objects of various weights and sizes.”

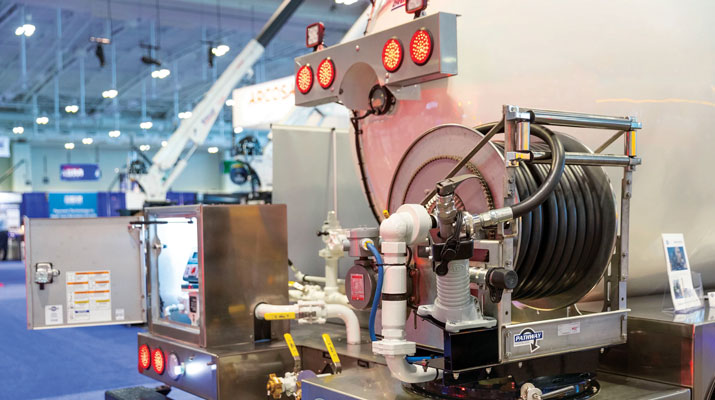

Swiveling hose reel offers flexibility

Morris, Minnesota-based Westmor Industries has showcased its patent-pending Pathway Delivery System at propane trade shows this year.

By enabling operators to choose whichever path and angle they prefer while delivering propane, the swiveling hose reel offers them more control over their deliveries than they’ve likely had before.

The CDTpro control system allows crane operators to maneuver the crane with a remote controller. (Photo courtesy of Stellar Industries)

Aside from increasing operators’ control, the hose reel will provide them more convenience and safety, too. For instance, they’ll be able to streamline their delivery processes, as they’ll only have to rotate and lock the hose reel into place, prior to guiding their hose toward the tank they’re servicing.

While rotating and locking the reel in place, they can utilize whichever path and angle is the most ideal for each of their respective deliveries. In turn, they’ll adapt to whatever they encounter on their jobsites, from uneven terrain to paths that would have been too long, rough or unpredictable.

“The Pathway Delivery System will help propane marketers with the ongoing operator retention situation, as they’ll have a safer and more ergonomic way to deliver propane than they ever did before,” Jason Soulon, regional sales manager at Westmor Industries, says.

By turning toward the direction of whichever tank an operator is delivering to, the Pathway Delivery System will also allow them to walk directly to their tank. Consequently, with the added flexibility the system provides, propane retailers won’t have to drag 100 ft. of heavy hose at an awkward angle or on an injury-prone path ever again.

The Pathway Delivery System, a swiveling hose reel, allows operators to gain more control over their propane deliveries. The feature on bobtails is designed for added convenience and safety for propane retailers. (Photo courtesy of Westmor Industries)

“Operators will have a safer, more comfortable way to deliver propane to each of their customers, leading to higher efficiency, less injury-associated downtime and a rise in retention,” Soulon adds.

“Without question, the Pathway Delivery System will positively impact the propane industry well into the future.”