Innovation in gas regulators

Today, I want to share innovations within regulators used in residential spaces that are now moving into agriculture, commercial and industrial spaces.

No matter the application, “out of gas” is a widely used term in the industry, but it isn’t defined from a regulatory sense. Most agree that it’s when the propane system no longer has enough gas pressure to support the appliance. I use the scenario, before sunrise at the coldest part of the day, the container capacity is low, and the gas demand is higher than the container can produce. It causes the pressure to drop and the appliance to stop working. The propane professional arrives to fill the container, and the sun has been up for several hours, and now the container has pressure. Was it out of gas or not?

Propane professionals who are filling containers ask the question, “Is it out of gas?” Now, with regulators that are providing underpressure shutoff (UPSO), they can rely on a mechanical device to make this determination.

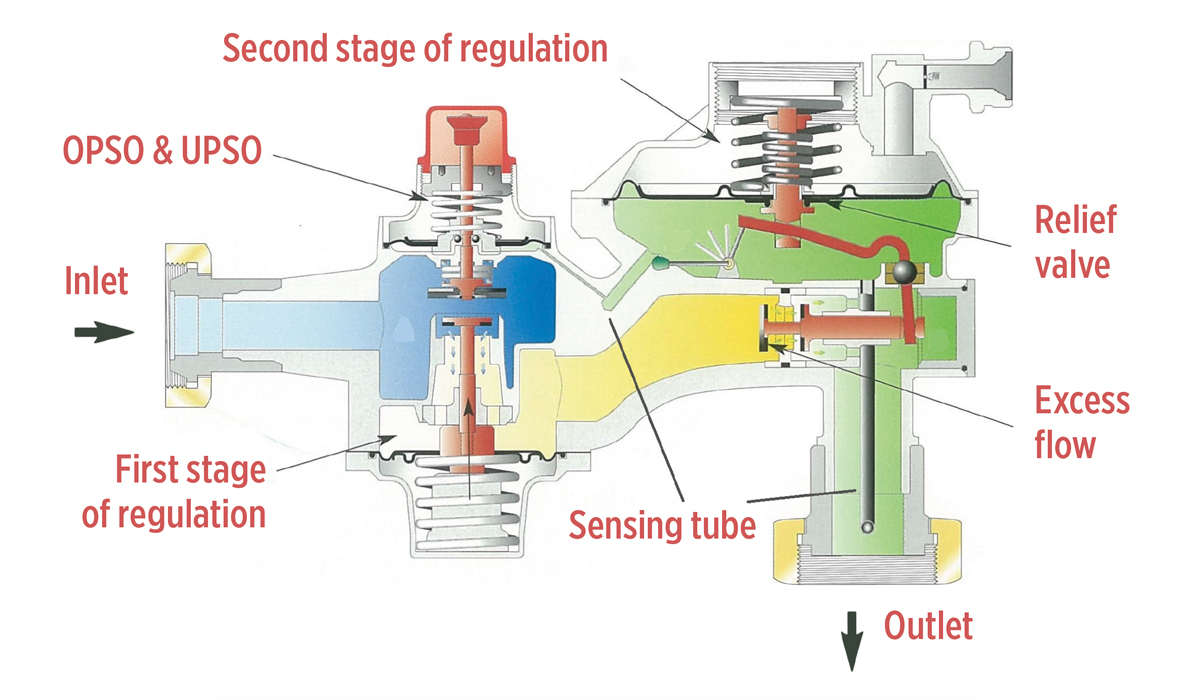

How does this work? These units vary by manufacturer, but the basic principles are the same: utilizing the ability to sense downstream regulator pressure by some means (typically a tube). When an underpressure event occurs, the diaphragm’s motion activates the mechanism, shutting off the gas flow on the inlet side of the first stage of the regulation orifice.

Underpressure shutoff (UPSO)

Normal operating downstream pressure compresses the OPSO/UPSO diaphragm spring and maintains a normal position by sensing the outlet pressure through the sensing tube. When the downstream pressure decreases, the diaphragm is forced down, and when the pressure reaches the set point, the mechanism activates by the UPSO spring, forcing the seat disc to close.

There’s also overpressure shutoff (OPSO) protection provided in these types of regulators. Think about a standard regulator. If there’s a tear in the regulator diaphragm, the regulator would vent until the source container is empty or someone is able to shut off the container. Regulators with OPSO sense the downstream pressure, and when an overpressure event occurs, there’s the motion of the diaphragm, which causes the mechanism to activate, shutting off the gas flow at the inlet side, eliminating the traditional release of gas vapors.

Overpressure shutoff (OPSO)

In the diagram, the OPSO/UPSO diaphragm is held down by the force of the pressure spring and senses outlet pressure through the sensing tube. When the outlet pressure builds, the diaphragm is forced up. When the pressure reaches the set point, the mechanism is activated by the OPSO spring, forcing the seat disc to close.

In either condition, the regulator can only be reset manually by a trained, qualified technician.

Visual indicators show that the regulator is in normal operation. Therefore, if the visual indicator is incorrect, the device has been activated and will have to be reset. The example shown here is a dual second-stage regulator, not to be confused with the typical first- and second-stage systems. This technology is now available on residential, agriculture, commercial and industrial applications.

Everyone appreciates new ideas in safety, and I hope this message will encourage “outside the box” thinking by looking into nontraditional technology that can help provide additional levels of safety for your customers.

Randy Warner is product safety manager for Cavagna North America. He can be reached at randywarner@us.cavagnagroup.com.

NOTE: The opinions and viewpoints expressed herein are solely the author’s and should in no way be interpreted as those of LP Gas magazine or any of its staff members.