New salt-cavern site shakes up western market with increased capacity

Western propane purveyors are leveraging the benefits of securing an enhanced and handy supply of LP gas by patronizing a vast new underground storage facility in central Utah.

With a capacity of 500,000 barrels of propane stored in giant salt caverns rivaling the size of skyscrapers, the just-opened Magnum NGLs site is already filled to the brim and sold out for the season.

“We had more demand than we had space,” says Brady Flamm, Magnum’s vice president of business development.

Customer drawdowns were under way in October as wholesalers and retailers readied for the arriving onslaught of cold weather.

“We’ve had steady supplies coming in over the summer, and we expect it to continue over the winter,” Flamm says, noting that participating parties – suppliers and buyers – cut their own pricing and volume deals, with the purchaser then making load-in arrangements with Magnum.

“We don’t market product,” Flamm says. “We just provide storage service. Each customer lines up their own supply, so the product is coming in from a variety of locations.”

Planning for the natural gas liquids facility began in 2008 with an initial focus on storing natural gas. The nation’s surging shale plays, though, have put those efforts on hold in favor of emphasizing butane and propane stocks.

It was apparent from the get-go that these two fuels presented a viable business opportunity, according to Flamm. Preliminary discussions with butane and propane providers throughout the region yielded significant demand for what Magnum was contemplating.

“We went out and talked to people in the beginning,” Flamm recounts, “and we started signing up customers before construction started.”

Company executives were confident that they could fill a supply void created more than five years ago when an underground propane storage facility in Moab, Utah, closed after it failed a mechanical integrity test. Those caverns stored about 5 million gallons of propane and butane.

“In the West, there’s just a real shortage of bulk underground storage, so supply has to be stored above ground in tanks. It leaves suppliers in the West short of propane in the winter and having to bring it in from other regions of the country and Canada,” Flamm says.

“We knew there was a demand in the West. When it got cold last winter, people came to us” in search of the anticipated storage capacities, Flamm says. “This will be our first heating season.”

Magnum NGLs is getting product in by truck and rail from all over the United States and Canada – primarily the Western U.S., Flamm says. Storage fees are collected in advance.

“It’s upfront at the beginning of the season; they pay before they start loading it in the spring and summer,” he says.

Located near Delta, Utah, the company has constructed a rail spur in-and-out terminal system branching off from existing tracks serving the adjacent Intermountain Power Plant.

“We have 10 rail spots and two truck spots,” Flamm says. “We expect that to be adequate,” adding that tank cars appear to be a more prevalent mode of distribution than over-the-road transports.“We feel that two truck spots are going to be plenty to meet the customers’ needs. It will be a pretty good mix.”

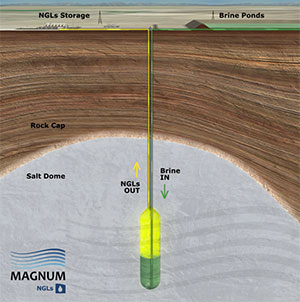

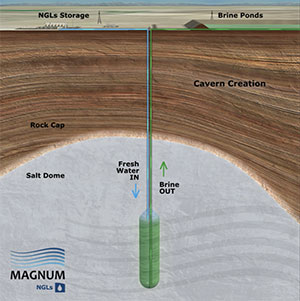

These diagrams show how the storage cavern was created with water, left, and how propane and butane are pumped out with brine. Image courtesy of Magnum NGLs

Magnum’s locomotive traffic has been busy as the propane flows to and from the location.

“Five times a week the railroad comes to pick up cars and drop new ones off,” he says.

Enhanced flexibility

Headquartered two hours away in Salt Lake City, the Turner Gas Co. is eager to access the convenient and heightened capacity that Magnum provides.

“There’s not really a lot of storage options in this region,” says Justin Turner, head of corporate development for Turner Gas. “We were extremely pleased to have it become available – that facility has become an extension of our office.

“From a logistics and operational standpoint, it gives our customers security in regard to availability and price,” Turner says. “It gives us flexibility to serve existing and new customers, and if there are winter shortages we will have that product available.”

Having invested heavily in mobile assets, the company is utilizing railcars and transports to access Magnum’s LP gas spigots after first filling the site with propane sourced from suppliers in Wyoming and elsewhere.

An executive at another large Magnum customer, requesting anonymity because of competitive reasons, reports that it will also be using transports and tankers to serve end-user needs throughout the heating season.

Expressing delight over the increased capacity along with the ability to buy lower in the summer and sell higher when the snow flies, the executive goes on to note that “there’s a pretty wide difference in summer and winter prices; now we can store some propane for our winter customers.”

Major U.S. propane hubs Mont Belvieu, Texas, and Conway, Kan., have underground salt-cavern storage. In the West, Arizona has underground storage in Adamana and Bumstead.

“Storing energy allows producers to lower risks and optimize resources by balancing fluctuations of consumer supply and demand,” says Magnum managing director Rob Webster, as he describes the “Gulf style” salt-cavern project.

Rather than tapping into an existing tapped-out salt mine, the Magnum site is a purpose-built facility. A giant drilling rig was brought in to bore down 3,000 feet into a huge previously undisturbed salt deposit. In a process known as “solution mining,” massive streams of water were pumped in to dissolve the salt and create below-grade caverns measuring some 900 feet high and 200 feet wide.

Pumps extracted the resulting brine, a mixture of salt and water, which is being stored in a nearby 157-acre pond. The contents of the brine pond are then pumped back into the cavern to push out the propane and butane as demand arises. Magnum is also looking into selling some of the excess brine to municipalities in search of a solution for winter snow- and ice-melting on roadways.

Photos Courtesy of Magnum NGLs