Propane regulator standards revised

The Underwriters Laboratories (UL) 144 technical standards committee has made a revision to the standard on propane regulators. The revisions focus on maximum inlet pressure ratings for second-stage or 2-psig service regulators, and requirements for regulators with an under-pressure shutoff (UPSO) device. The standards were scheduled to be published in July 2021.

Until now, second-stage and 2-psig service regulators had a maximum inlet pressure of 10 psig. This is not a problem for the typical residential application where you have a container and a two-stage regulation system. With community systems, which typically service several residences through distribution lines coming from a large storage container, the operating pressure of those distribution lines was regulated to be a maximum of 10 psig. This is because the second-stage regulator (a part of this system) has a maximum inlet pressure of 10 psig.

This can cause operating issues in peak demand situations and cause outages, which lead to safety concerns. The revision allows for operators to increase the inlet pressure above 10 psig and allow for more efficient and safe operating systems.

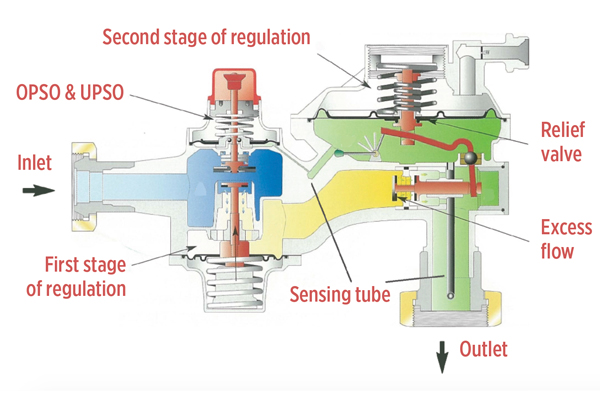

The other revision requires regulators to be equipped with UPSO protection. A UPSO device shuts off the flow of gas when the outlet pressure of the regulator reaches a set point. Once activated, it remains closed and has to be manually reset.

Why is it important?

I think of the scenario when the container pressure decreases due to low liquid volume in the container, the temperature is low, and the demand is high. Because the container cannot provide enough vaporization to maintain the operating pressure for the appliance(s), they stop working. However, as soon as the temperature warms up, the container resumes vaporization. The pressure in the container builds and continues to allow the flow of gas into the system. This explains why, when a customer calls you and states they are out of gas, the propane professional might find that the system has pressure.

Manually resetting a UPSO device at the regulator requires training to do properly. Even if another source of propane is connected to the system upstream of the regulator, no flow of gas downstream of the regulator will occur until it is reset. Since the customer would not be aware of how to reset the regulator, a trained propane professional technician would have to be sent to investigate and resolve the condition that caused the activation of the UPSO before reinstating service to the system. The National Fire Protection Association requires a leak check when an interruption of service has occurred and before service can be restored.

How it works

Under normal operation, the downstream pressure compresses the UPSO diaphragm spring and maintains a normal position. The device senses the outlet pressure through the sensing tube. When the downstream pressure decreases, the diaphragm is forced down, and when the pressure reaches the set point, the UPSO spring forces the seat disc to close off the inlet flow of the first stage of regulation.

There are visual indicators to show that the regulator is in normal operation. If the visual indicator is not correct, the shutoff device has activated and will have to be reset.

These updates to the standards will allow innovation in regulators and continue to ensure safe and reliable products for the end user and the propane industry.

Randy Warner is the product safety manager for Cavagna North America. He can be reached at randywarner@us.cavagnagroup.com.