As you work through peak demand periods this winter, it’s also a good time to assess your propane storage capacity. Are you able to make it through crunch times without running out? Can you keep all your customers supplied without delays or interruptions? Or could your business benefit from having additional propane storage to ensure reliable supply for current customers and expand to new ones?

As you work through peak demand periods this winter, it’s also a good time to assess your propane storage capacity. Are you able to make it through crunch times without running out? Can you keep all your customers supplied without delays or interruptions? Or could your business benefit from having additional propane storage to ensure reliable supply for current customers and expand to new ones?

While U.S. propane production has increased in recent years, that increase has been driven largely by a growing export market, and that market dynamic is impacting how and when you buy propane, says Alan Groene, CHS Propane senior account manager for Wisconsin and Michigan. “Over the past three years, the percentage of total U.S. production that is being exported has gone from 50 percent to 68 percent, and that trend is expected to continue. As a result, the U.S. propane industry needs to look at how to more efficiently purchase, market and distribute propane.

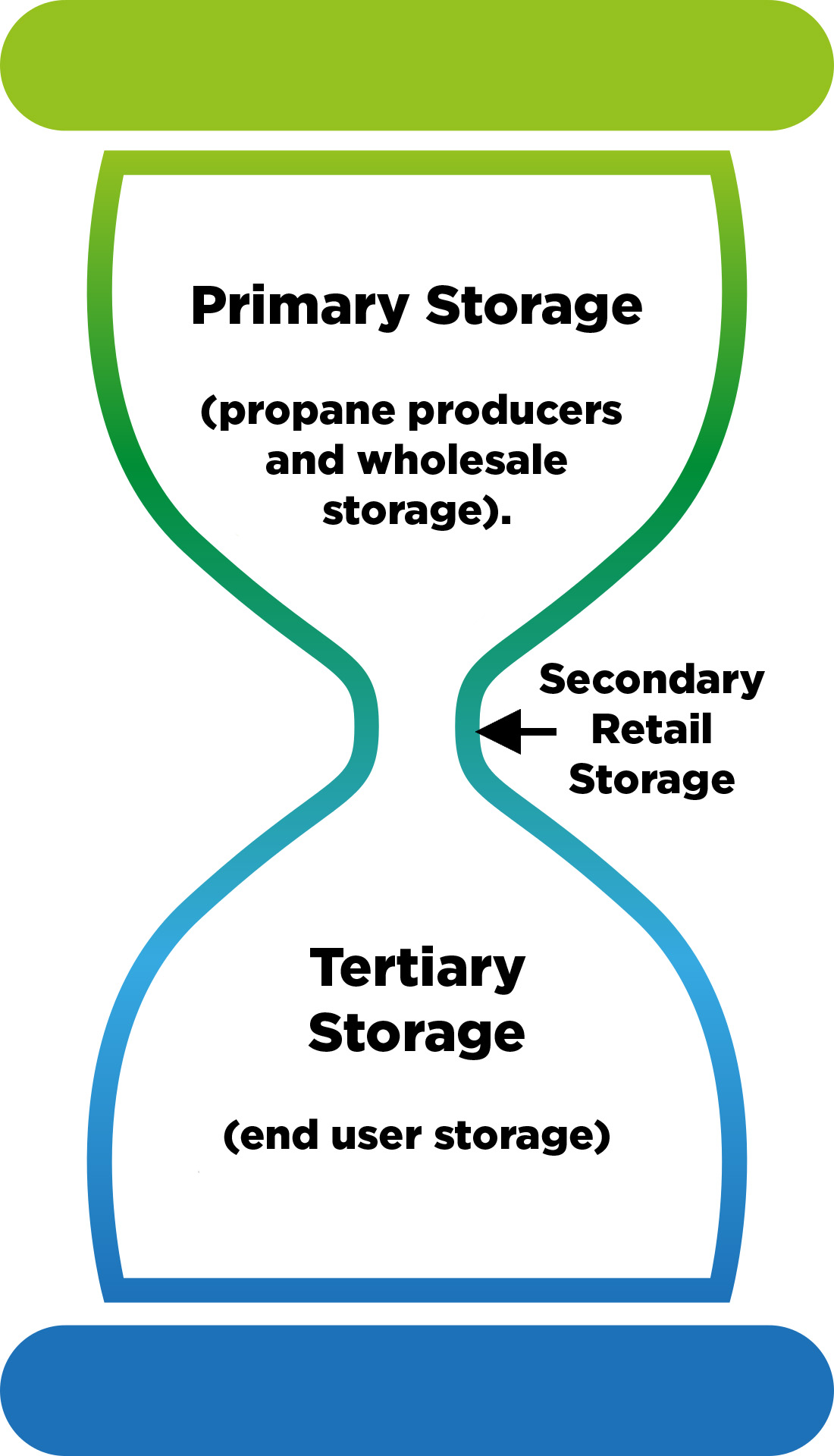

“Adequate storage is an important part of that efficiency. And having more storage closer to the end user is always better for U.S. consumers,” he says. “This can be achieved through adding storage on the retailer side, as well as using monitors and scheduled deliveries on the consumer side. These additions enable the industry to leverage tertiary (end user) storage in the country, which is a large portion of the overall U.S. storage system.”

Photo: CHS Propane

A good way to visualize today’s propane industry is to think of it as an hourglass, he says, with the top chamber representing primary storage (propane producers and wholesale storage), and the bottom chamber representing end user tertiary storage. The thin middle point reflects the secondary storage level, and its limited amount of retail storage currently available. It continues to be the biggest pinch point in today’s supply chain. Adding storage may be the best way for many accounts to widen that bottleneck.

How much is enough?

Twenty years ago, the propane industry recommended 14 days of storage capacity during peak demand. “That’s not affordable for many businesses, but a good current rule of thumb in most U.S. geographies is to have at least seven to 10 days of storage capacity. Those in cooler northern climates need at least eight to 10 days of supply. Currently, only about 5 to 10% of propane retailers have enough storage based off their geographical region and logistics,” notes Groene.

Right-sizing storage for your company’s specific needs depends on a variety of factors. As the chair of the Wisconsin Propane Gas Association Supply and Infrastructure Task Force, he recommends answering these questions:

• How many times do you turn over your existing tanks each season?

• How many reliable supply sources do you have?

• How far away are those sources?

• How many carriers do you regularly use?

• Do you have a winter only source and carrier(s) to get that product?

“Your CHS account manager can go over each of these points to help determine if additional propane storage would pencil out for your business,” says Groene. “Winter is a good time to make those decisions because you’ll have enough time to order equipment and arrange for installation come late spring or early summer.”

Making expansion affordable

Retailers don’t have to shoulder all the burden of expansion costs upfront. The CHS Storage for Pennies program provides a lease-to-own option on new bulk fuel storage and equipment, explains Kenton Sonnenburg, CHS Propane energy equipment manager. “Customers can lease equipment, then pay for it over an extended time with payments included in the price of propane purchased from CHS, at a manageable rate. We can also help customers choose the equipment and features that provide the best solutions for their operation, then source the equipment and line up installation with reliable vendors.”

CHS coordinates financing through a third-party source but handles all the payments to make the process convenient. “Most customers pay off their investment in five to 10 years,” says Sonnenburg.

“Recent weather patterns, allocations, and fears of additional tariffs could lead to a new push to increase propane storage in 2025, so we’re encouraging any accounts thinking about it to make a decision as soon as possible to avoid delays in sourcing equipment or installers. Currently, it takes about four months to get most new tanks.”

The cost of steel has shown some strength, and we have already seen increases in the prices of valves and tank equipment, adds Sonnenburg. “A new 30,000-gallon tank now costs 35 percent more than it did five years ago, and that trend could continue.”

Learn more about the CHS Storage for Pennies program at Storage-For-Pennies.pdf (chsintheknow.com) or call 1-800-852-8186 and press 1.

Propane marketers should work with their CHS account managers for help determining if they need additional storage. Learn more by visiting CHS Propane Insights or by calling 1-800-852-8184.

Header image: CHS Propane

This page was produced by North Coast Media’s content marketing staff in collaboration with CHS Propane. NCM Content Marketing connects marketers to audiences and delivers industry trends, business tips and product information. The LP Gas editorial staff did not create this content.