The age of the gauge is gone.

For the past 30 years, things in the tank monitoring industry have remained mostly the same. Read- ready gauge technology has relied on mechanical gauges and floats inside the tank to give a reading, usually displayed as a percentage of how much liquid is in the tank.

For the past 30 years, things in the tank monitoring industry have remained mostly the same. Read- ready gauge technology has relied on mechanical gauges and floats inside the tank to give a reading, usually displayed as a percentage of how much liquid is in the tank.

The read-ready gauge technology relies on a 30-year- old patent for the mechanical gauges and has remained largely the same since that time. Historically, these gauges are +/- 5% inaccurate, but can be even more inaccurate, depending on the age of the gauge. In addition, the possibility for normal wear and tear from the elements remains high, and to replace this gauge, the entire tank would need to be emptied.

For many people, this option for tank monitoring is less than ideal. Most of these people find that they don’t really know how much is in their tank at a given time since +/- 5% has become an industry average. Pair this with occasional problems with bleeder valves and the effects could potentially result in catastrophic damage and even lost lives.

For many people, this option for tank monitoring is less than ideal. Most of these people find that they don’t really know how much is in their tank at a given time since +/- 5% has become an industry average. Pair this with occasional problems with bleeder valves and the effects could potentially result in catastrophic damage and even lost lives.

One of the biggest challenges in the industry is the traditional way of thinking, according to Kevin Jaffe, CEO of Sonariot. Many times, the adage of “Well, we’ve always done it this way and it just works” gets used. Jaffe says people rarely ask “Is there a better way to do this?”

Up until now, there really wasn’t a better way to monitor tanks. But now, there is new technology on the horizon. The age of the gauge is gone, and sonar tank monitoring is the way of the future.

Sonar tank monitoring is a new solution to the industry that works on both pressurized and non-pressurized tanks. In a world where being precise with measurements and accuracy reign supreme, nothing beats sonar. As a time-tested technology used in military, scientific, and commercial environments, two companies has decided to bring this technology to the forefront of the industry.

Photo: Sonariot

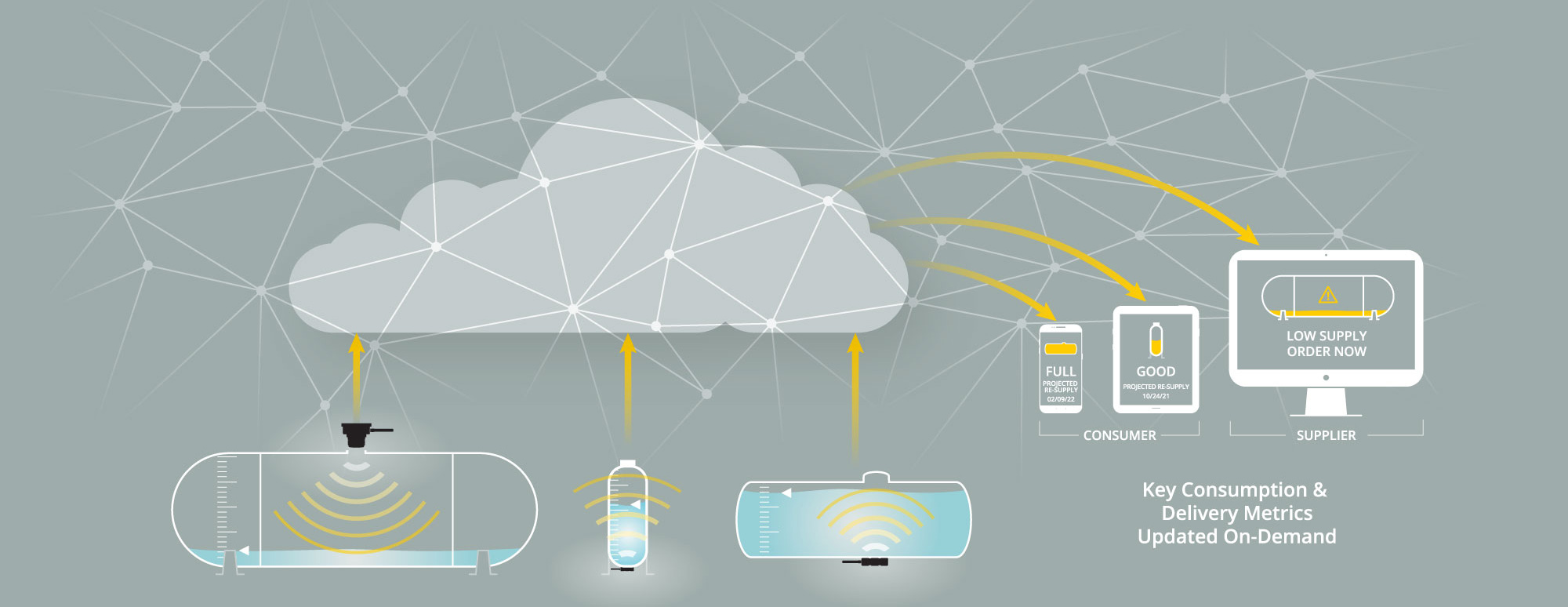

Sonariot and Mopeka Products have made it their mission to bring sonar tank monitoring to everyone – from those having barbecues to those running multi-million- dollar businesses. Mopeka Sonar Tank Monitoring Sensors are revolutionizing the industry, utilizing the Global SIM 4G LTE CAT M1 and NB-IoT so that no one needs to worry about being on a specific network.

Not only are the products themselves revolutionary, but the additional services through Sonariot allow access to top problem-solving teams and the technology to back them up. With Mopeka’s cloud-based software, customers can manage and monitor tank levels from any device that is connected to the internet. This gives customers the power to make the best decisions possible, according to Jason Peck, co-owner and executive vice president for Mopeka.

Sonar tank monitoring takes the level of uncertainty down to +/- 1% or less, meaning that companies can truly know the levels their clients are at. As a result, they can better streamline their operations and delivery schedules, save money on transportation to and from job sites, and they can ensure customers are receiving product exactly when they need it. In this day and age where Customer Service and Experience are everything, the precision, accuracy and convenience offered by sonar tank monitoring is game changing… and is a true differentiator for the Propane and Liquid Commodities industries.

Learn more about Sonar Tank Monitoring at sonariot.com

This page was produced by North Coast Media’s content marketing staff in collaboration with Sonariot. NCM Content Marketing connects marketers to audiences and delivers industry trends, business tips and product information. The LP Gas editorial staff did not create this content.

Header photo: Sonariot