Fun in the sun

The vacation brochures don’t lie. The Atlantic Ocean water is the truest blue, and swaths of small boats bob gently at the many inlet docks that make Florida such an attractive destination for retirees and vacationers alike.

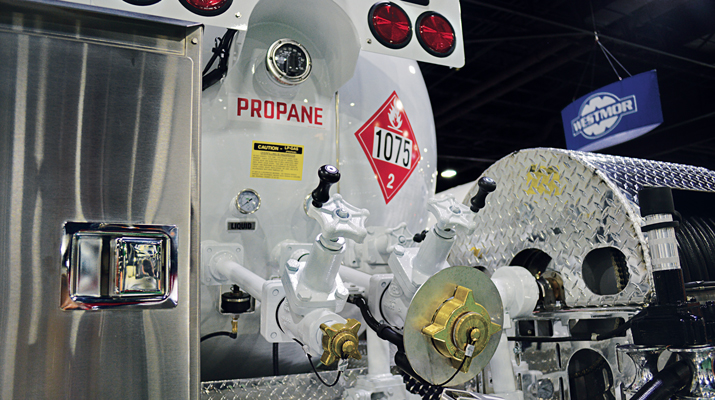

Since opening in July 2000, Sea-3 Florida has already exceeded propane sales expectations. |

By lunchtime, the temperature has nudged to a record-high 83 degrees. Truck drivers stepping down from their rigs squint into the bright sunshine and take in the tropical breeze rolling in from the coastal waters.

“This feels like August,” observes Pat Patterson, terminal operations manager at the 26-million gallon import facility that Sea-3 Inc. opened at the Port of Tampa some 18 months ago.

The feeling is far from the chaos that most propane dealers normally experience when the Super Bowl is still a few days away.

The entire Sea-3 Florida facility is monitored and controlled from a computer console in the main office. |

Despite the summer-like surroundings, the conversation always seems to revert back to winter cold – or the lack thereof. With just over a full month left in the 2001-02 heating season, the propane industry is limping through its fourth warmer-than-normal winter in the last five years. Coupled with a lingering national economic slump, this year’s mild temperatures have propane retailers praying for a late, prolonged blast of cold weather.

Maybe his relocation to sunny Tampa wasn’t such a good choice after all, a visitor suggests to Patterson.

The veteran of Detroit-area winter wars shakes his head remembering the bleak, snow-whipped winter days up North. “No, I’m done with all that. We’re at home here now,” Patterson says with a laugh.

The Tampa plant is equipped to load four tanker trucks at once. |

Hot Start

The $23 million Sea-3 Florida terminal has been operational since July 2000. Ten workers staff the site, which operates around the clock every day of the year.

The new facility sold 72 million gallons sold of propane in its inaugural year, eclipsing company estimates by 20 percent. By late January 2002, Sea-3 Florida was on pace to do 65 million gallons this year, off budget by 7 to 8 percent due to the lack of heating degree days.

The plant’s efficiency is drawing customers from throughout the Southeast. |

“We’re not happy about it,” Patterson says. “But it’s the same story everywhere you look. Our industry needs the cold winters to thrive, and we just haven’t gotten them the way we’d all like.”

Still, Sea-3 Florida already has made a substantial impact. Its opening increased wholesale propane storage capacity in the region by 10 times, according to Michael Tracey, vice president of marketing.

The Sea-3 Florida facility is designed to withstand hurricanes and 15-feet of flooding. |

The facility was built to supply wholesale distributors serving business and residential customer within a 150-mile radius of Tampa Bay. The company plans to sell 100 million gallons annually, which equals half of the consumption in a 125-mile radius.

The plant’s efficiency already is drawing rave reviews and customers from beyond the Florida market that Sea-3 Florida was designed to service. Customers from neighboring states including Georgia and North Carolina are returning this year after positive experiences during the supply crunch record cold winter months of 2001-02.

The main office building also houses vital pumping equipment. |

While transports lined up to wait up to six hours for a load from the Dixie Pipeline during last winter’s crunch, the new Sea-3 Florida plant was loading more than 100 trucks per day with no more than a two-hour delay.

The fully computerized facility is designed to load four tankers simultaneously, although only three are operational to date. Each truck takes just 20 minutes to fill.

“It’s great for the drivers and the dispatchers because there is no idle time that is so common elsewhere,” Patterson explains. “That’s important because most of these guys are getting paid by the load.”

Why Tampa

Sea-3, a Houston-based import terminal firm that is New England’s largest supplier and marketer of propane, chose the Tampa site for several reasons:

- It has a deep-water, unrestricted, first-class port.

- The regional market had been supplied from domestic producers that had to deliver product over long distances.

- The region had no large storage facilities, and

- The market had been growing at twice the national industry average.

Sea-3 leases its 12-acre site from the Tampa Port Authority. The terminal can receive propane by ship, barge and tank trucks. Although it has no rail loading facilities, Patterson notes that the property sits adjacent to an active railroad spur and the facilities can be added in the future.

The Site

Sea-3 is a Houston-based import terminal firm that imports from three major sources – Algeria, Venezuela and the North Sea. The Tampa import facility, which can accommodate a ship measuring 950 feet in length, averages four shiploads per year.

The operating logistics for a propane importer are a delicate balance of demand, storage capacity and the whims of Mother Nature. A fully loaded ship will completely fill the 26.5 million gallon storage tank, so Patterson must time the supply voyage to arrive before his tank hits empty.

Twenty-six million gallons of propane are stored at minus-40 degrees at the Sea-3 Florida plant. |

Once the hulking ship arrives at the terminal, its cargo is transferred to above-ground storage at a rate of 523,000 gallons per hour. Because of staffing requirements on the ship, at the dock and at the storage facility during an unloading, the entire Sea-3 crew must be available for the 51 straight hours it takes to unload the ship.

Like the above-ground storage tank, the refrigerated ships carry product at minus 42 degrees. Product flows through 2,000 feet of low-temperature steel pipe to the storage tank, which uses a chemical refrigeration system to keep the propane liquid. The massive storage tank, which is surrounded by six inches of foam insulation, sits on a pile-supported foundation to prevent the ground below it from freezing.

It’s design was worldwide state-of-the-art at the time of its construction, notes Patterson, who was hired to run the Tampa facility six months before it opened. A 30-year employee at Sunoco, Patterson ran a jet fueling facility at a Miami airport before joining Sea-3.

Not All Sunshine

The same weather that beckons visitors to sunny Tampa carries concerns for the storage site. The Florida coast gets hammered during hurricane season each year. Violent tropical winds in excess of 100 mph often are accompanied by torrential rains that cause dangerous flooding.

According to Tracey, the storage facility was designed to withstand a Category 3 hurricane and flooding up to 15 feet.

The trailers that arrive in Tampa for a load of propane cannot hold product at sub-zero temperatures. The propane must be warmed through a heat exchanger to raise the temperature to 50 degrees before it is loaded into the pressurized tanker truck. Each heater can service two trucks at once.

Two persons monitor the fully computerized operation from a control console in the main office. The plant has a diesel-run generator to provide backup power to run the computers, flare and most other critical functions in the event of a power outage.

Trailers are filled to 87 percent capacity, and the computer issues a release and order with net gallons automatically adjusted. Each driver is responsible for knowing how many net gallons his rig can take.

Safety Concerns

As one of the largest propane storage facilities in the United States, Sea-3 Florida has been under particular scrutiny following the Sept. 11 terrorist attacks in New York and Washington, D.C.

Patterson says there is a regular stream of local, state and federal agencies attending to security and related concerns in the event of further terrorist activities.

Routine visitors to the site include the U.S. Coast Guard, Tampa Fire Department, Florida Department of Law Enforcement, Tampa Port Authority,U.S. Immigration and Naturalization Service, Florida Department of Agriculture (which regulates propane in the state) and the local Sheriff’s Office.

There also have been visits by the U.S. National Guard concerning new requirements for proper identification for truck drivers and personal vehicles.

“Understandably, everything regarding national security has been ratcheted up here since the events of Sept. 11,” Patterson says.

“In some ways, I think others are more concerned about the facility than we are; we feel very good about the measures that have been taken to make this the most secure facility possible. At the same time, we want to be good neighbors to everyone. Whatever we need to do to satisfy the Port Authority and all the other regulatory agencies, we plan to do.”

Several operational changes have been implemented since the World Trade Center attacks last fall.

The facility’s main gates no longer are left open. Approaching vehicles are monitored by camera as they pull up to the gate. Once allowed inside, the gates are closed behind them.

Likewise, the walk-through gates that used to be closed but unlocked now require a security approval before opening.

Sea-3 Inc.

Sea-3 is a wholly owned subsidiary of Transammonia Inc. of New York since 1985. provides New England with more than one-third of the 300 million gallons the region needs for its manufacturers and distributors each year.

The company was founded in 1973 by Gazocean, an international trading and shipping firm based in Paris, France. At the time, it appeared that the United States would become a major importer of propane due to rapidly declining gas reserves. Company officials originally planned to have three propane import terminals on the East Coast.

Gazocean chose its New Hampshire site near the seaport of Portsmouth because of product demand in the Northeast and because it was the greatest distance from the domestic propane deposits of Texas, Louisiana, Kansas and Oklahoma. It also was the closest port to the exporting countries.

When U.S. demand for propane leveled off in the mid-1970s, Sea-3 put its expansion plans on hold.