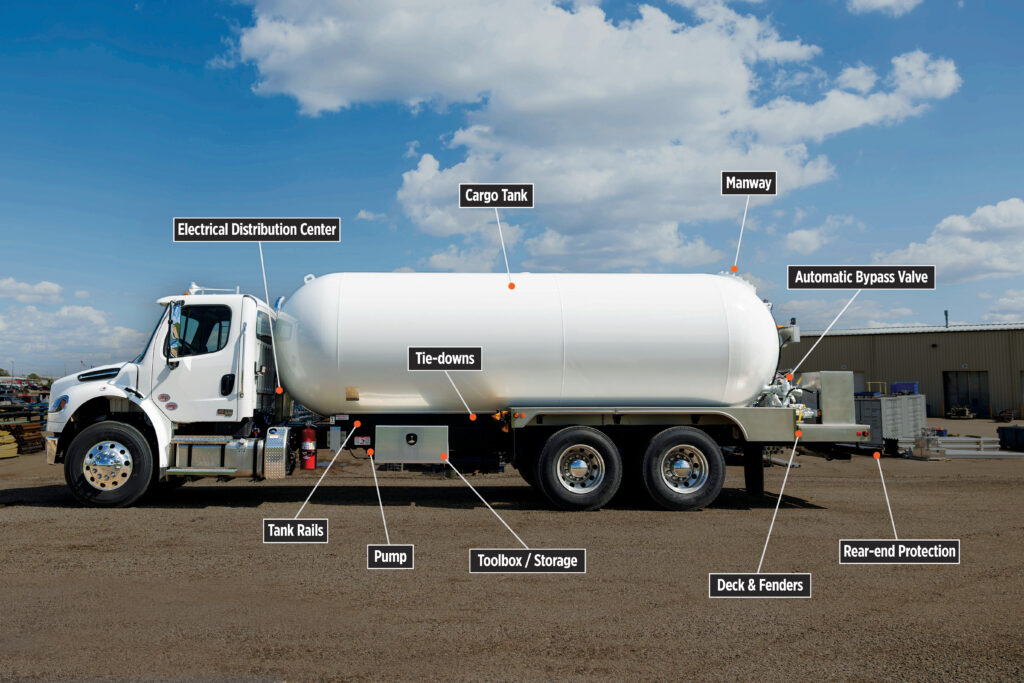

Breaking down the anatomy of a bobtail

Comparing today’s bobtail to the models that traversed the roads of yesteryear, the propane industry now places a clear emphasis on driver comfort, convenience and safety.

Mike Walters remembers his early days in the industry. He started driving a bobtail for California retailer Pargas in 1979. He recalls the all-day effort of picking up a used bobtail and making it roadworthy, from preparing the truck to run reliably to ensuring the lights would even work. What he doesn’t recall are the many comforts of driving through the Central Valley.

“Nowadays, the driver gets in the truck, and they have all the comforts of home,” says Walters, now with Superior Energy Systems. “They’re driving these Kenworths or Peterbilts – they’re real trucks – and they’ve got Bostrom air-ride seats, AM/FM stereo with AC and cruise control, and God knows what. It’s a completely different world.”

That “different world” is the world in which bobtail builder Westmor Industries lives. For years, the Minnesota company has placed its focus on driver comfort and convenience, driver retention, and safety.

“If the driver can’t physically use the truck, if he’s not comfortable, if he’s tired, if he’s climbing too high, if he’s pulling too hard on the hose, if he’s just physically frustrated, that makes the bobtail feel harder to use, less productive, less safe,” says Jason Soulon, regional sales manager at Westmor.

As LP Gas visited with industry members to learn more about the features available on today’s bobtails, the driver was at the center of many discussion points.

The chassis

When it comes to propane marketers building or buying a bobtail, the brand of truck is always among the first considerations. Many choices exist, including models offered by Ford, Freightliner, Kenworth and Peterbilt.

“The customer typically has a preconceived or an existing preference based on their experience, their local service, what they just feel is best for their business,” Soulon says.

Where are they operating geographically? Is the land mountainous or flat? What’s the maximum road speed?

“How do you want that truck to perform every day for your business?” Soulon says.

The bobtail’s overall performance is based on the marketer’s powertrain needs – with the engine, transmission and rear-axle ratio, for example.

“People who buy trucks forget that it’s not just about the horsepower,” Soulon says. “In terms of how that truck will perform, it’s about the torque, the rear-axle ratio. You can have an engine with all the power and torque in the world, but if the rear axle is geared wrong, that truck is going to drive poorly.”

Marketers should also consider their suspension options. Soulon says suspension technology has progressed over the years, with air-ride suspension seeing a greater adoption.

Driver assistance technologies – anything that automates driver functions – is another featured part of the chassis. Roll stability, collision mitigation and visibility systems are a few examples.

“Every bobtail we build these days, at the customer’s selection, has a backup camera,” Soulon says. “That can evolve to having front-facing cameras, side-facing cameras, bird’s-eye view, driver-facing cameras. And some of those cameras incorporate AI.”

The trend, he says, is toward more driver-facing cameras, which can recognize drowsy or distracted drivers, but they also can be used to exonerate a driver in an accident.

“Camera systems have improved and become more economical, increasing the safety level of the truck,” agrees Rob Vandemark of IPS.

Maneuverability is another key characteristic of the chassis. Two decades ago, a truck’s turning radius was less than impressive. Much has changed.

“These days, the truck manufacturers, the axle manufacturers have made product improvements to make the front axle turn better,” Soulon says. “We always spec a setback front axle on a single-axle bobtail. That provides better maneuverability. More and more customers are saying, ‘I need to get this bobtail in a very tight spot. I need the maximum maneuverability I can get.’”

The cab

Among the driver’s first thoughts inside the cab: How comfortable am I? Fortunately for drivers today, cabs have evolved.

In recent years, some truck manufacturers have addressed the narrow feel of the cab and given drivers the physical space they need to work comfortably and efficiently. After all, many marketers now include a tablet or other device that runs their data management system. Some have backup camera monitors, radio remote systems and consoles for the driver’s other possessions.

“Mostly the chassis that the tank and components are mounted on are built with the driver’s comfort and safety in mind,” Vandemark says. “Today’s trucks are built so the driver can get in and out of the truck easier, reach controls inside the cab better and see around the truck better with the help of cameras.”

Getting into and out of that cab (ingress and egress) is an especially important consideration for the driver. Some truck manufacturers have given more thought to that over the past five to 10 years and incorporated more driver-friendly designs, Soulon says.

“It used to be the climb up and out of the cab was clumsy and dangerous,” he adds. “That’s a big driver fatigue point and doing that 20-plus times a day is a potential hazard.”

The cargo tank

Marketers must consider the truck’s tank size and payload capacity. The industry norm in most of the country is 3,200 gallons, Soulon says, with that size increasing to 3,400 or 3,499 gallons in northern parts of the United States.

“What we’ve seen over the past 15 years is a trend from a single-axle truck to a tandem axle,” Soulon says. “It comes down to efficiency and payload.”

Marketers gain more maneuverability with a single-axle truck, and while they lose some maneuverability with the tandem axle, they gain in their payload. For example, marketers delivering large loads to agricultural or commercial accounts, where maneuverability is less paramount, would most likely choose to increase their payload with a tandem (three axles). In this case, the standard cargo tank size at Westmor increases to 5,300, 5,500 or 6,400 gallons.

The issue of driver availability could impact the type of bobtail and cargo tank size that a marketer chooses, says Mike Hennen, general manager of the Truck and Trailer Division at Westmor. He compares a marketer having two bobtails and two drivers to a marketer having one driver who’s hauling a larger tank.

“If you have a 3,200-gallon bobtail or a 3,400, that bobtail may be capable of pushing out 500,000 gallons annually,” Soulon says. “But you take that up to a 5,500-gallon tank or a 6,400-gallon tank, and we commonly see customers delivering a million-plus gallons off that bobtail.”

Companies like Westmor that manufacture the cargo tank and upfit the truck have found ways to lighten the tank and improve the overall design, owing in part to aluminum baffles and internal piping. Westmor’s tanks also feature fully welded rails and one 3-in. relief valve instead of two 2-in. valves.

While marketers decide the shiny new features of their bobtails, a trend of tank maintenance neglect in the ensuing years is causing more corrosion damage to the tank, according to Westmor. This can result in tens of thousands of dollars in damage.

Marketers can apply what Soulon calls a “rock guard” on the lower third of the tank during the upfitting process to help reduce damage.

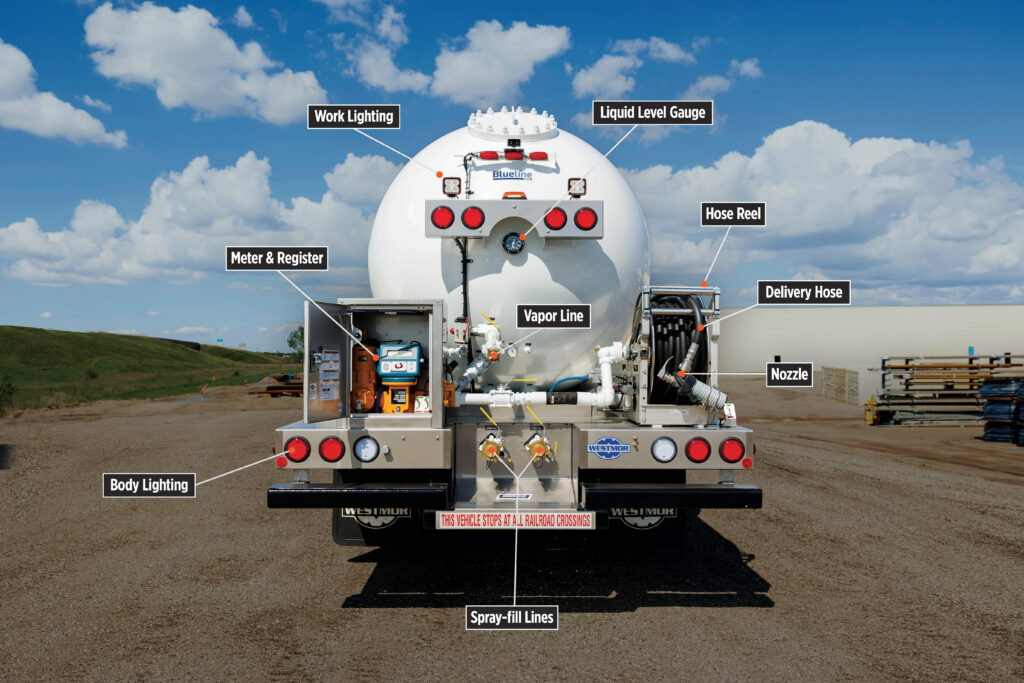

Loading and delivery systems

At the back of the bobtail, the cargo tank offers advanced loading and delivery systems to make the marketer’s job easier.

For example, Westmor has designed a stainless-steel deck (the Ergoload) that lowers the spray-fill and vapor-return lines to waist height, giving drivers a more convenient and comfortable way of loading and unloading their bobtails.

Dual-loading capability is another trend giving marketers with larger bobtails the ability to load as fast as possible.

“When you have a 5,000-[gallon] or larger tank, you want to load it as fast as possible, and that’s based on how many gallons a minute you can put into the tank,” Soulon says. “And if your bulk plant has two loading lines, but your bobtail only has one, you’re losing the benefit of speed. So we build many of our tandem-axle bobtails with dual spray-fill loading points.”

Marketers are configuring their bobtails to match the bigger pumps and faster loading systems installed at many bulk plants today, Hennen adds.

Self-loading capability, though prevalent in the western states for decades due to the large number of satellite plants and the distance between deliveries, is a growing trend throughout the industry. Instead of marketers using a bulk plant pump powered by electricity, they use the pump on the bobtail to draw propane from the plant. The method is less efficient and harder on the pump, but it’s used at satellite plants without power or during disaster recovery efforts when systems are down, Soulon says.

On the delivery side, Vandemark says, “The APSCO Thermaflow propane bobtail stabilizer has helped increase the delivery rate of bobtails using the engine coolant to help add vapor head pressure to the product pump, increasing the gallons per minute during the colder months. Anything a propane company can do to increase more stops in a day will definitely help the bottom line.”

Safety systems

New technology has added to the overall safety of today’s bobtails.

Among them, safety interlocks have evolved over the past 15-20 years, and marketers are installing them to prevent pullaways around the loading line or the domestic tank. If the line remains connected during a pullaway attempt, a proximity sensor prevents the transmission from switching into gear.

Brady Griffith, a regional sales manager at Westmor, says the Allison automatic transmission prevalent on Westmor’s bobtails allows it to build more safety features into the vehicle.

Hose reels

Advancements with the hose reel have added safety and convenience during the delivery process.

Drivers now have assists that can help them guide the delivery hose to and from the reel. Wireless handheld remotes, like those from Base Engineering, can initiate the process automatically, among many other functions. Westmor’s Pathway delivery system also allows the driver to turn the hose reel 90 degrees toward the curbside and physically make it easier to pull.

“That’s the most physical thing the driver does, other than climbing up in the cabin – pulling 100 to 150 feet of hose out toward a customer’s tank, and then you get it back to the truck 20-plus times a day,” Soulon says. “Anything that could make that process less physical, less strenuous [is beneficial].”

Some truck models also offer two hose reels, again increasing efficiencies for drivers delivering to a variety of customer accounts.

Even a 2025 LP Gas Hall of Famer, Walter Smith of Full-Circle, contributed to this part of the bobtail. He developed a series of listed hose-end and hose-reel swivels. The hose-end swivel allowed for a 360-degree rotation of the filler valve at the end of a delivery hose.

Meters, registers and pumps

Electronic meters and registers are the norm today, syncing to the data management system inside the cab. The electronics are now the brains of the bobtail, as the system receives the information from the register, tracking customer sales, invoicing and more.

“In-cab electronics are constantly advancing, and the electronic register heads are keeping up with the changes,” Vandemark says. “Anything to help the driver improve their delivery route, make ticket calculations and be more accurate with the product delivery.”

Higher-flow pumps have also hit the market in recent years as more marketers want to deliver the product faster.

“You can’t necessarily do it on a residential delivery into a domestic 500 or 1,000, but if you’re making deliveries into other types of containers, you can increase the delivery rate from 65 gallons a minute up into the 90s,” Soulon says.

Related Articles

How the bobtail powers the industry and drives opportunity

How can propane companies bring out the best in their drivers?