Cogeneration: A combined effort

Market favorable for gas-powered systems that turn waste heat into productive uses

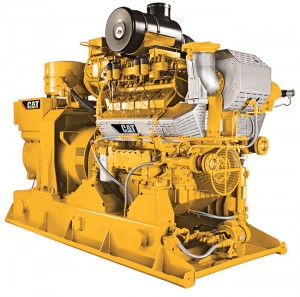

Shale gas development brought on by the process of hydraulic fracturing has helped make market conditions favorable for onsite, gas-fueled power cogeneration, according to a Caterpillar white paper.

The 13-page white paper details opportunities for industrial and commercial facilities to explore the economic possibilities of cogeneration with today’s natural gas and propane engine technology providing cost-effective electricity and heating.

While the white paper gives much attention to natural gas, its author, Michael Devine, the gas product marketing manager for Caterpillar’s Electric Power Division, says propane can be just as valuable in cogeneration because of its availability in areas without natural gas infrastructure and as a more cost-efficient, cleaner alternative to diesel.

“There are a number of different types of applications that could be running diesel-fueled engines to power systems – hotels, refineries, mining sites, places creating food-type applications, some textile plants – but where it could be done far less expensive with propane and, in particular, if there are emissions requirements they have to meet,” says Devine, whose report is titled “More Than Heat and Power: A Fresh Look at Cogeneration.”

Cogeneration, also called combined heat and power, takes heat otherwise wasted and extracts it from the engine for productive uses. A growing number of cogeneration applications have moved into the mainstream, taking cogeneration beyond the simultaneous generation of electricity and hot water or steam, the white paper notes. Today’s usable engine outputs also include heated air and chilled water produced from absorption chillers. The heated air can feed equipment such as kilns and dryers, while the chilled water can be used for space or process cooling.

Users of today’s generating technologies can realize electrical efficiencies up to 45 percent and total resource efficiencies up to 90 percent, Devine writes. Caterpillar says separate grid electricity and gas boilers often provide less than 50 percent efficiency.

“With these projects, oftentimes you are doing them for the energy first. There’s a need for it,” Devine says. “On the Caribbean islands, there are no natural gas pipelines, but propane is readily available. You take that energy and use it to create electricity, and oftentimes you are creating it for less than it costs to buy from the electric utility.”

The white paper also details low-intensity cogeneration applications where simple heat recovery in applications having about 1,000 annual operating hours can improve the economics of many electric power projects. These include commercial real estate, light industry, hospitality and food processing. Cogeneration systems can also add value by providing backup power.

The decision to pursue cogeneration opportunities becomes one of economics, Devine says. His report poses the question: Will savings on energy costs and revenue from electricity generated provide adequate return on the investment in equipment? He also offers potential physical or cost barriers that would make a project impractical.

“If you do things smart and in a way that makes sense, there are a lot of opportunities for propane in many areas, particularly those not well serviced with gas lines,” Devine says.

Larry Osgood, president of Consulting Solutions, says cogeneration projects can be a challenging proposition for the propane industry. But a propane marketer in the right location – away from natural gas mains and amid high electricity rates – can benefit greatly.

“They use a ton of gas,” he says. “Basically a system uses about 1,000 gallons of [propane] per kilowatt. An 80-kilowatt system at a medium-sized hotel or a residential care home burns about 80,000 gallons a year.”

To learn more about cogeneration or to obtain a copy of the white paper, click here.