In the Know: Propane inventory in the summer-build season

In the Know is a monthly partnership between LP Gas magazine and Propane Resources. Our focus this month is on propane inventory, addressed by supply and risk management expert Jeff Thompson.

In the Know is a monthly partnership between LP Gas magazine and Propane Resources. Our focus this month is on propane inventory, addressed by supply and risk management expert Jeff Thompson.

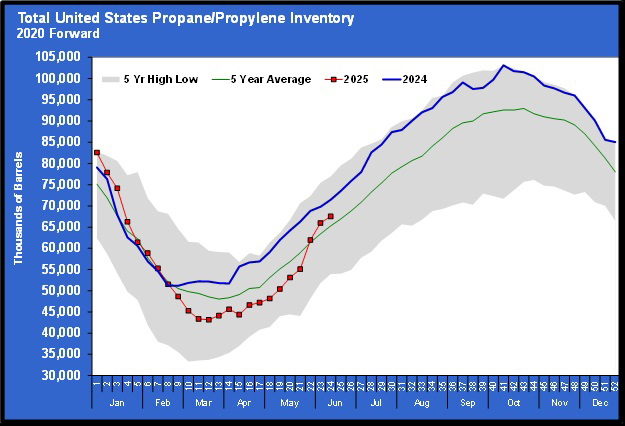

Q: Could you provide a snapshot of the propane inventory picture going into the summer-build season (both on a national and regional scale) and explain what this means for propane retailers?

A: As we head into the dog days of summer, propane inventory builds are quickly becoming the dog. Traders are watching the inventory builds closely. Every week that we do not build 2.5 million barrels or more, it adds to every future week needing a larger build than the previous week.

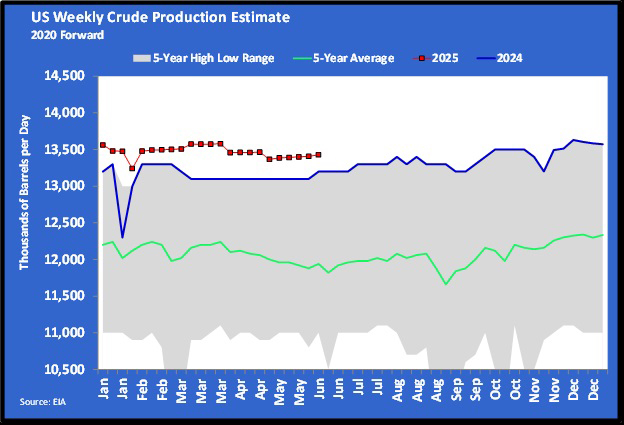

The propane industry has been spoiled over the past two build seasons with extraordinary builds. Simply put, the U.S. propane market has been out of balance. There was more supply than demand. Now the pendulum is swinging the other way. There is more demand than supply, and U.S. inventories are balancing.

Two years ago, exports were averaging 650,000 barrels per day (bpd) September through December. Last year, exports increased 25 percent during the same period of 2015 to 812,000 bpd. If 2017 increases 25 percent from the same period in 2016, it would equal 1 million bpd, which is about the export pace we were experiencing in May 2017. This is going to significantly impact inventory builds through summer and into winter.

Based on current reporting and recent history, total U.S. inventory will end in a range of 75-80 million barrels by the end of build season in September. This would be about 80 percent of inventory levels over the past two years heading into winter.

Regional breakdown

PADD 2 (Midwest) likely will end in a range of 26-29 million barrels.

PADD 2 includes Michigan storage. This is often overlooked when people look at PADD 2 numbers and think Conway, Kansas, is the storage facility for PADD 2. Conway is the primary storage here, but Michigan plays a critical role.

Michigan storage, generally speaking, is fed out of western Canada. This can give the impression that PADD 2 is in good inventory shape. All recent infrastructure and facility upgrades are to move liquids to the Gulf Coast, not to PADD 2. Any stronger-than-usual demands strain Conway storage.

Based on past two-year averages, PADD 2 would end up in March 2018 in a range of 11-14 million barrels, which is in the longer-term normal range. A grain drying season like in 2013 will quickly expose Conway inventory vulnerability. A draw like that would pull PADD 2 down an additional 7 million barrels. Over the past two decades or so, the PADD 2 March inventory low was 5 million in 2003. In the 2002–03 season, PADD 2 began below 50 cents per gallon, peaked at about $1 and, by the end of March, pulled back to 50 cents. The question is how much of the 26-29 million barrels projected in PADD 2 will be in Conway?

PADD 3 (Gulf Coast) looks to end in a range of 40-43 million barrels. This is well behind the past two-year September average of 62 million barrels. Traders have become accustomed to 60 million barrels in the Gulf Coast. Forty million barrels going into winter would be well below their comfort zone.

If PADD 3 draws like it did over the past two winters, the projected inventory level at the end of March 2018 would be 13-17 million barrels of propane. In other words, PADD 3 inventory would sit at half a month’s worth of exports. It is possible, but one hiccup in the distribution chain in PADD 3 could make for very volatile price swings.

Traders are beginning to demand higher build numbers in PADD 3. This demand will be reflected in price movement. For stronger builds to develop primarily in PADD 3 and secondarily in PADD 2, the propane market will be forced to move up in price. The incentive for larger builds is more money for the holder of propane gallons. With 40 million barrels of propane going into winter, PADD 3 only holds a bit over a month of export capacity.

PADD 1 (East Coast) is getting ready to start looking a lot differently from a reporting perspective. With the completion of Mariner 2 pipeline upgrades, Marcus Hook will begin to fully function as an export facility. What happens at Marcus Hook will influence PADD 1 builds. Significant builds will only occur if prices are high enough to incentivize keeping gallons in Pennsylvania rather than putting them on a boat. Look for PADD 1 inventory to rise and fall with the flow of boats going into and out of Marcus Hook.

Propane inventories will have to build higher and faster as we go through the summer, or prices will take care of it for us.

Jeff Thompson is a supply and risk management expert for Propane Resources. He can be reached at jeff@propaneresources.com or 888-739-6732.