Know the safety features of propane autogas systems

We know that propane autogas is a safe and reliable fuel, proven by the thousands of vehicles – buses and fleet vehicles – that have been using autogas across the U.S. Some key attributes of propane autogas are:

- Lower flammability range than conventional gasoline.

- Odorized for easy detection.

- Environmentally friendly, with a national average carbon intensity score of 79 and the potential to reach a score of less than 20 with renewable propane.

- Nontoxic and presents no hazards to soil and groundwater.

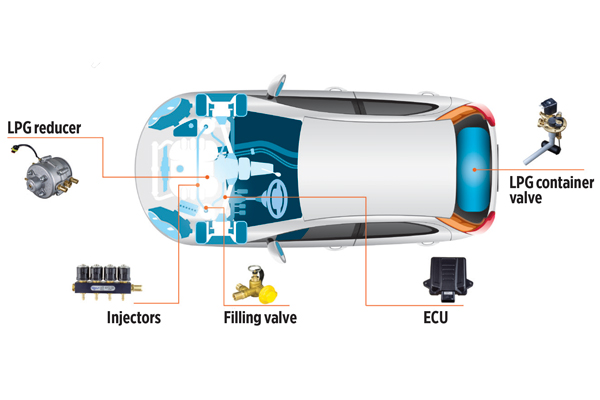

The fuel systems for propane autogas products have been innovated for optimal use of the fuel, with low environmental impact. They are designed and engineered with safety features, including pressure-relief valves, shut-off valves that detect fuel line ruptures, and overfill prevention devices. A few key safety features to remember are:

- Containers are equipped with safety devices, including overfill prevention;

- Constructed from carbon steel;

- Are 20 times more puncture-resistant than conventional gasoline and diesel tanks.

Dispensing autogas safely

Autogas dispensing stations are similar to gasoline or diesel fueling stations in appearance, but they have important differences:

- They are closed, pressurized systems to keep propane in its liquid state.

- The dispensing nozzle must be connected to the container before fueling. Ensure the connection type: low emissions quick connect (K15), or screw-on 1 ¾-in. ACME.

- The overfill prevention device (OPD) will automatically close the flow when the tank is full.

When filling a vehicle using an autogas dispenser, remember these steps:

- Prepare. Park on level ground, turn off the ignition, confirm vehicle fuel type is propane, inspect filling connection, ensure safe filling area, and discharge any static electricity by touching a grounded object.

- Connect. Remove fill cap or open access door, inspect fill valve, attach appropriate adapter if required and connect nozzle.

- Fill. Turn on dispenser, open the nozzle, wait for the OPD to automatically stop the flow.

- Shut down. Turn off the dispenser, close the fill nozzle, disconnect nozzle, store hose, disconnect adapter (if applicable), check for leaks, reinstall cap and close access door.

Autogas dispensing stations should have operating and filling instructions along with emergency shutdown instructions. Any uncontrolled release can be extremely hazardous, and ensuring clear instructions and signage is important. In the case of an uncontrolled release, steps to remember are:

- Take action. Evacuate the area.

- Be aware of your surroundings. Shut down the dispenser if possible.

- Get help. Call for help once you have evacuated and are in a safe place.

- Do not interfere with emergency responders when help arrives.

The Propane Education & Research Council (PERC) has many resources available to assist propane marketers in obtaining training. One such resource is Dispensing Propane Safely: Autogas. The program includes an on-the-job training worksheet that provides the resources to determine if the learner can demonstrate the appropriate level of knowledge to dispense propane autogas safely. The program can be accessed online, at no cost, through PERC’s Learning Center: training.propane.com.

Randy Warner is the product safety manager for Cavagna North America. He can be reached at randywarner@us.cavagnagroup.com.

NOTE: The opinions and viewpoints expressed herein are solely the author’s and should in no way be interpreted as those of LP Gas magazine or any of its staff members.