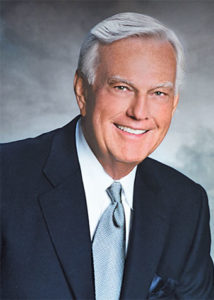

LP Gas Hall of Fame profile: Richard Barker

The 2022 LP Gas Hall of Fame dinner and induction ceremony will take place April 23 at the Omni Nashville Hotel in downtown Nashville, Tennessee. Inductees are Richard Barker (Silgas), Nancy Coop (Cetane Associates), Joe Rose (Propane Gas Association of New England) and Doug Auxier (Auxier Gas). Get more information here.

When his critics laughed and dispelled his plans to build an underground propane storage cavern in the country’s heartland, Richard Barker never wavered. He spent much of his career convincing others to consider the alternative.

As a young boy growing up in the small town of Windfall, Indiana, Barker worked at the family business, Solar Petroleum and Hardware. He rode with the oil tank wagon drivers and learned how to make deliveries and handle 60-pound cylinders.

Barker also saw an opportunity with propane in the 1950s, as many of the oil customers were converting to LPG.

But the Depression was in his father’s mind because the downturn impacted Barker’s grandfather. This created an unwillingness in Barker’s father to spend the needed capital on a new business segment. Over the course of two years, Barker convinced his father to make propane a bigger part of the business, which allowed Barker to launch a heating company.

Solar’s propane business grew to where Barker could install his first bulk plant. In less than five years, the company was selling more than 1 million gallons of propane and had enjoyed a significant increase in furnace installations.

With a strong consumer base in place in the early 1960s, Barker convinced his father to seek a buyer. RediGas’ purchase of Solar closed the chapter on Barker’s first experience in business and in propane, and later led to Petrolane’s purchase of RediGas.

But it didn’t change the aggressive way in which Barker pursued industry opportunities, especially when it came to propane operations, sales and storage.

A new home

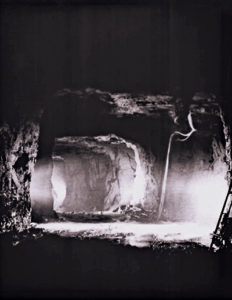

Silgas’ annual propane gallon sales reached 150 million wholesale and 18 million retail. (Photo courtesy of Richard Barker)

In 1968, Barker ascended to general manager and president at Indiana-based Silgas, then owned by Paul Ogle, who Barker says was like a father.

Barker had gotten involved in state associations, conducting seminars on how propane businesses could gain operational efficiencies, including through the use of multi-fill valves, degree-days and routing systems. He met Ogle during one of those meetings, and Ogle called later in the year with a job opportunity.

Silgas became a major part of Barker’s life, and it was where he made some of the most dramatic changes for a company and for the industry.

Barker noted how the company was driving hundreds of miles to load gas. He watched as the oil embargo of the 1970s – which cut oil exports to the United States and created an energy crisis – impacted Silgas’ supply contracts. He also testified at Senate hearings in Washington, D.C., on the effect price controls of the time were having on small propane dealers.

The events also forced Barker to learn new ways to supply the business. He got more involved in brokering supply deals for his company and for others’ – a process he came to enjoy.

By the fall of 1974, with everything that had happened with supply, Barker saw the need to develop a significant pipeline terminal in Seymour, Indiana.

“I had one heck of a time convincing Mr. Ogle that we could afford to do it,” Barker says.

The decision was made easier with Silgas’ location near a Texas Eastern Pipeline facility. Two years later, in 1976, the Seymour Pipeline Terminal was in full service, featuring 40 34,500-gallon tanks that increased Silgas’ storage capacity to 1.3 million gallons.

In its heyday, Silgas’ wholesale business was selling 150 million gallons annually with the help of a 50-transport fleet, buoyed by Barker’s brokering ability to move propane around the country. The company also developed a strong industrial business.

“Trucking became a big thing for me,” Barker says.

Barker never imagined Silgas’ wholesale business would grow so quickly, and, combined with the company’s retail business (which grew to 18 million gallons annually), the terminal became strained. Frustrations over working with the railroads only added to Barker’s belief that something else was needed in Seymour. The solution happened to be right below it.

What lies beneath

Parts of Indiana are known for high-quality limestone. How ironic that some of the most suitable strata in the United States happened to be below Silgas’ new pipeline terminal.

“We would not only be able to supply the demands equal to the past years but would increase the gas supply for [250] miles surrounding the area many times over and have storage space available for leasing to other companies,” Barker writes about the underground propane storage cavern in a first-person account of his career.

Barker’s vision of constructing a 500,000-barrel cavern in Seymour was met with ridicule. He recounts the engineering company that he approached in Tulsa, Oklahoma, laughing at him.

“They said there’s no way a company your size can build a cavern like that,” Barker says. “I left Tulsa with my tail between my legs.”

But Barker again didn’t waver. He found the best people for the project, including a consultant who formerly worked for that engineering company. Don McCarthy had experience in underground LP gas storage and believed in the project, Barker says.

They wrote the contract, which called for Silgas to buy the needed equipment, including the loaders, booms and electric hoist. They gathered employees with mining experience and others from Silgas. Construction ran 24/7 for seven months.

Completed in 1979, Silgas’ cavern – 400 ft. underground, 425 ft. deep and covering about 10 acres beneath the pipeline terminal – could store 21 million gallons of propane.

“I honestly think it’s the will of God to do what I’ve done,” Barker says.

Barker sold Silgas to Brooklyn Union-owned Star Gas in 1988 and oversaw the wholesale division for 17 years. Later, after Inergy acquired the company in 2004 and Barker headed toward retirement a year later, the cavern was named the Richard R. Barker Cavern. Today, Crestwood owns and operates the Seymour facility.