Texas manufacturer revives decades-old propane tank design

UV Doron isn’t sure why it happened. For some reason, in the early 1960s, the standard design for steel transport tanks carrying propane changed.

Over the past 10 years or so, Doron and his company – Exosent Engineering in Navasota, Texas – have brought the old design back to the industry. He says it provides stability and safety.

Doron says that in the 1930s, a sturdy, low-center-of-gravity transport tank was patented in the United States. The tank, asymmetrical in shape, was the standard for decades. Then, in the early 1960s, the industry shifted toward a more symmetrical tube design that was higher off the ground.

The new design might have evolved because quenched-and-tempered steel entered the market in the 1960s. It’s a stronger steel, but Doron says tank manufacturers need almost three times the machine capacity to form asymmetrical shapes. It made more sense for them, while using quenched-and-tempered steel, to form symmetrical tanks with a higher center of gravity.

Exosent Engineering has reintroduced asymmetrical transport tanks, both designing and manufacturing them. The tanks are closer to the ground than standard tanks. The company also makes uniquely shaped bobtail tanks.

“As engineers, our goal is to make the public safer,” Doron, 53, says. “In our tiny sandbox, that’s what we’re doing to try to improve life in this country.”

▶ ‘Outside thought’

Doron, president of Exosent, was born into the steel industry. His grandfather, Samuel Bendor, started a small sheet-metal shop in 1956 in Israel. The company grew and eventually made crude oil storage tanks and oil and gasoline trailers.

Doron’s father, Daniel Doron, took over the family business in 1973. He moved to the United States in 1985 and launched Domatex, a Houston maker of roll-off containers for the scrap industry, three years later. The company transitioned into a manufacturer of industrial tank trailers.

UV Doron started his career in the U.S. Navy as a machinist mate, working as a steam- and boiler-room mechanic. He became vice president of Domatex in 2005 but left the company in 2008 to attend graduate school. He earned a master’s degree in mechanical engineering at Texas A&M University.

Doron co-founded Exosent, which is Latin for “outside thought,” in 2010 with Andrew Duggleby, a scientist with expertise in fluid mechanics and computational analysis. For the first 18 months, the company focused on designing various products, including vacuum and oil-field trailers, but not tanks.

Then a friend talked to Doron about propane transport tanks and trailers. Doron grew curious, conducted research and learned about the 1930s low-center-of-gravity tank, which was still the standard in Europe.

“We found a picture of the European trailer and saw the benefit,” Doron says. “We are mechanical engineers, so we knew a tank closer to the ground would be more stable.”

Doron also came across a 2007 study by the U.S. Department of Transportation (DOT) and Battelle, a research-and-development firm based in Columbus, Ohio. The study was titled, “Cargo Tank Roll Stability Study.”

The study – which is still on the Federal Motor Carrier Safety Administration’s website – looked at the causes of truck and tank rollovers and suggested potential remedies, one of which was lowering the trailer’s center of gravity. According to the study, lowering the center of gravity by only 3 in. can reduce the likelihood of rollovers by 10 percent.

Doron extrapolated those numbers and calculated that lowering a tank’s center of gravity by 14 or 15 in. cuts the chances of rollover by more than 30 percent.

A flyer published by the U.S. DOT, based on the 2007 study, reports that about 1,300 cargo tank rollovers are reported annually. Causes of rollovers include driver error, vehicle condition and load size, but the flyer doesn’t mention tank design. That’s where Doron thought Exosent could make a difference.

Exosent completed the design of its asymmetrical tank in 2014. Most of the tank is about 39 in. from the ground. According to the U.S. DOT/Battelle study, a standard industry tank is about 53 in. from the ground.

▶ Slosh and baffles

Doron says other factors play into the stability of Exosent’s tanks. For example, the shape means little to no slosh.

“Think about it,” Doron says. “You have about 40,000 pounds of liquid propane in that tank. If the trailer travels at 65 mph and must come to a rapid stop, the liquid surges forward, putting all that force on the truck.

“If slosh is there, you get a continuous backward and forward wave action that pushes the trailer into instability,” Doron says. “Removing that slosh effect creates more stable stopping events.”

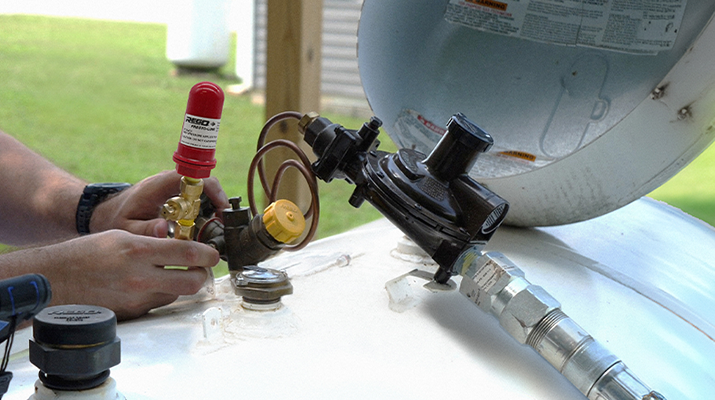

Exosent has designed its own aluminum baffles that control and redirect the flow of liquid inside the tank to help reduce slosh. While standard baffles are solid metal, Exosent’s are perforated, which allows fluid to flow through the metal but slows down the fluid. That reduces shock to both the tank walls and the baffles, Doran adds.

In addition, Exosent’s tanks have air foils or “wings” on the back, which lowers wind drag and, in effect, fuel consumption and costs.

Exosent has not stopped innovating. The company is partnering with Nexio, a chassis designer and maker in Nacogdoches, Texas, on a gooseneck tank trailer that can be hauled by a 1-ton pickup truck.

“We always keep pushing the envelope,” Doron says.

Related Articles

Exosent Engineering bobtails, transports have low center of gravity