Propane industry moves to create national safety data repository

At the beginning of 2024, Eric Kuster and his colleagues at the Propane Education & Research Council (PERC) started tracking the number of news headlines related to propane incidents across the country. They sensed an uptick in these types of headlines.

“It’s not that we thought there were more incidents,” says the senior vice president of safety, education and compliance at PERC. “It’s just that we saw more incidents in the headlines of papers and different periodicals.”

Around the same time, a PERC study on the perceptions of propane showed an increase in the number of consumers questioning its safety.

“At first, we thought it was from negative data from the cooking studies that had been done, the gas stove ban [attempt] and all that,” Kuster says of the federal government’s efforts in 2022 and 2023 to gather information on gas stove emissions and modify energy conservation standards for consumer conventional cooking products.

“When we dug into the numbers, it wasn’t” related to the cooking studies, Kuster adds. “It was regarding propane incidents and explosions.”

In an era of heightened media attention, internet chatter and cameras in many smart devices, news of a propane-related incident – no matter the details of how it occurred – can travel fast and influence the public’s thought processes.

The increased media attention and the perception study results had Kuster and PERC thinking more about how people perceive propane.

Their time spent tracking the news headlines about the incidents and pondering the public’s perceptions of propane, however, is only part of the story. These developments have helped to underscore the fact that PERC, considering all its propane safety and training offerings to both the industry and consumers, can take yet another step to enhance safety: By creating a national repository of propane safety data that can serve as the foundation for new safety and training programs and support mechanisms for the industry.

“I would say it’s less about the data, and it’s more about the culture,” says Chris Wagner, vice president of codes, standards and safety at the National Propane Gas Association (NPGA).

▶ Only snapshots of data

The lack of a central repository of propane-specific data available to the industry marks one of its greatest challenges – and a key reason PERC is working alongside NPGA to build such a database and ultimately improve the safety culture within the industry.

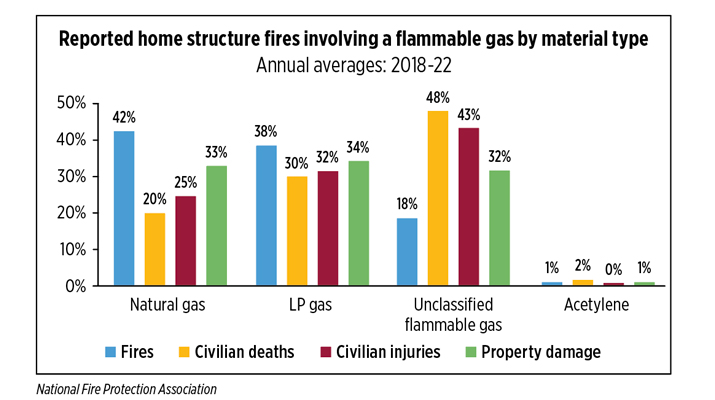

About 25 years ago, very little was known or understood about propane incident data, Kuster says. Steps have been taken in the last quarter century to improve data collection. The industry has a relationship with the International Association of Fire Chiefs, as they work together on PERC’s Propane Emergencies program, and PERC looks at data from the National Fire Incident Reporting System, a resource under the U.S. Fire Administration.

“We’re still trying to get clean data,” Kuster admits. “That’s a challenge, for sure.”

As Wagner explains, “snapshots” of data exist across various organizations and government websites. For example, the North American Industry Classification System can benchmark safety data according to industry standards, providing a relevant understanding of Occupational Safety and Health Administration (OSHA) injury and illness rates, but it’s not propane-specific. The same issue exists with tracking vehicle incident rates.

Looking at the broad categories of data, propane industry employees are most impacted by slips, trips and falls, and strains and sprains, Wagner says.

“It’s very difficult to narrow down, and if you were to look at the OSHA published data or the Bureau of Labor and Statistics data, it doesn’t get granular in its information to show what are the true injuries that happen,” he says.

Wagner joined NPGA in May 2024 after spending 14 years across AmeriGas’ safety and legal departments. In replacing the retired Bruce Swiecicki at NPGA, Wagner was tasked with performing the same technical code duties that Swiecicki undertook but also broadening the role to include industry safety initiatives.

While at AmeriGas, Wagner says, he could describe the types of slips, trips and falls; the weather conditions under which they occurred; the time of day; where they occurred within the employees’ delivery routes; and more. The nation’s largest propane retailer could then take that information and refocus its safety strategy to address the incidents at their core.

It’s that detailed information that Wagner, Kuster and their industry colleagues hope to bring to the rest of the industry on a national level.

“It’s a matter of getting down to the really bare bones of where, why and how an incident is occurring and then utilizing that data to build safety programs and checklists and other things that will be of value to the propane marketers in the industry so that they can set themselves up for success,” Wagner says.

For Kuster, it all comes down to the frequency and types of incidents as well as the trends the industry can detect from the data.

“We’re really trying to trend those types of numbers to see directionally where we need to put our resources for safety training and education programs,” he says. “Where do we need to spend industry dollars effectively so that we can reduce incidents?”

▶ Defining an incident

The process of collecting and interpreting incident data isn’t a new concept for the propane industry.

In fact, near the end of Wagner’s tenure as chair of PERC’s safety and technical training working group, in July 2023, industry leaders were in the early stages of talking about the possibility of disclosing incidents and collecting information to benefit the industry. However, he recalls a general apprehension from companies about the process of sharing information that could potentially be used competitively against them.

“When I moved to NPGA, I knew, from a business standpoint, where some of the apprehensions were, and that allowed me to reach out to Eric and start formulating a gameplan of, ‘OK, how can we do this differently?’” Wagner says.

When Wagner contacted Kuster, the PERC leader was already exploring current data available to the industry and tracking a run of negative press clippings devoid of data indicating the underlying causes of incidents.

“Eric was looking at things from a grander scheme, and then I came in to represent NPGA in a safety position, and it was just natural for us to determine, ‘OK, we need to break down these barriers. We need to figure out how we’re going to get these results, and we need to figure out how to take the next step in our educational journey,’” Wagner says.

For the industry to build a repository of information that’s actionable for its members, it first must define a propane incident and identify the type of data it would want to collect from an injury and vehicle incident standpoint, Wagner says.

“Once we can define an incident, then we can start working toward actually identifying systems that are capable of tracking the information,” he adds.

Kuster and Wagner have also identified natural disasters and crisis management as key elements of the program and therefore would require the industry to also define a crisis.

A group of propane marketers, of varying size and geographic makeup, has been invited to participate on a “benchmarking team” to identify key parameters and help advance the project. An in-person summit was in the works for September.

The meeting will help determine the path forward and the potential systems they would put forth in a funding request before the council, though Wagner says, “I don’t know how many meetings it’s going to take to get a consensus.”

Ultimately, the chosen system would allow industry members to upload their incident data anonymously and glean reports to build safety programs, much like Wagner did at AmeriGas.

▶ Investments in safety

Kuster says PERC is already making a large commitment to safety, spending 20 percent of its budget (about $7 million annually) on various initiatives. It looks to raise the bar even further by creating this incident tracking repository, which could lead to even more safety and training tools for the industry.

Wagner adds context to the project when he says the industry has been blessed with “an extremely safe product,” and few incidents occur within a fixed gas piping system that’s installed and tested by a propane marketer. This initiative, he says, doesn’t revolve around catastrophic incidents. Instead, it’s based on defining an incident and then using data for knowledge and prevention.

“We’re really looking at safety as the large umbrella that covers all aspects of our business, and how do we start reducing risk or at least being better at recognizing risks that we put before ourselves and then taking the appropriate steps.”

Kuster adds, “When we talk about an industrywide culture of safety, it comes down to: How do we get our people thinking every day about safety? How do we reduce injuries and keep out of those headlines?”

The propane industry is moving closer to yet another solution – one based on data.

Related Articles

Superior Energy Systems advocates propane fire safety training

Injury cost estimator underscores importance of a safety culture