Quality Steel’s American Welding & Tank purchase helped define its identity

To understand the Quality Steel Corp. of today, one must trace a timeline into its past.

And it’s not necessarily the very beginning of that timeline, the company’s 1957 founding by Lowry Tims in Cleveland, Mississippi, that has entirely shaped that identity, though the Tims family and its southern roots are certainly part of the story.

But one could point to Quality Steel’s 2013 acquisition of American Welding & Tank (AWT) as arguably the most notable notch on the company’s path to becoming a major U.S. propane tank manufacturer.

That acquisition not only grew Quality Steel’s footprint from its one location in Mississippi to having a balanced U.S. presence, as well as expanded its tank offerings, but it also changed the look and cultural feel of the larger company.

“That footprint became much bigger than Cleveland, Mississippi,” says Lance Dalton, the vice president of sales and marketing.

Sean Picou, vice president of operations, had been working for AWT, managing its West Jordan, Utah, plant, when Quality Steel acquired the company from Taylor-Wharton International over a decade ago. The deal also included AWT’s Fremont, Ohio, location.

Picou points to a different style of leadership under the Tims family, including Lowry’s son Jim, currently chairman of the board, that set the tone for the new-look company. Picou also cites Dalton, Lynn Hardin (the current president) and Virgil Mullins (former vice president of operations) for contributing to that cultural change.

“It was a family feel,” Picou says. “They cared about you, your family and your challenges, and how they can help you grow and make you more successful, because they genuinely cared, and in return, the business does better too.”

Picou says it was that rejuvenation around the company – not only the family aspects but the entrepreneurial feel and how employees could be open with one another – that attracted him to stay with Quality Steel after the acquisition.

“One of our leadership behaviors is to be fun-loving,” he adds. “It’s what we try to not only look for when we’re attracting new talent, but we also encourage each other to continue to be fun-loving.”

Certainly, it’s not all fun and games at Quality Steel. As Picou says, “We like to have fun and we like to joke around, but we are very serious about the work that we do.”

In Quality Steel’s view, that work focuses on its people – about 400 employees strong, including its sister company LP Cylinder Service – who can join the company’s employee stock ownership plan (ESOP) after meeting its eligibility requirements. Company leaders say the ESOP is another way to strengthen employee dedication to its mission.

“The leadership here has done a good job of grasping that the most important asset in this company is our people,” says Payton Tindall, director of operations, responsible for the three Quality Steel locations as well as LP Cylinder’s Shohola, Pennsylvania, location.

“It’s very easy to say that, and I’ve heard a lot of companies say that, but it’s a little different when you actually do it,” Tindall adds. “There is an emphasis on how you treat people, how you communicate.”

Tindall is based in Cleveland, Mississippi, where Quality Steel serves as one of the few well-known and respected employers. In such a small town (with a population of around 10,000), the locals learn quickly about a company’s culture and reputation. Its headquarters location is deeply involved in community initiatives as well.

“There’s a lot of industry in West Jordan and Fremont compared to Cleveland,” Tindall says. “And essentially, there’s only one other business of this magnitude in this area. So reputation and that small-town feel are very important here.”

In an industry where heavy steel grinding and welding is the norm, safety is paramount, and Quality Steel believes its approach to safety is another area that sets it apart.

“It’s our No. 1 core value,” Picou says. “That’s just not wallpaper.”

When Tindall became director of operations, he took the company’s safety initiatives to another level, Picou notes. Tindall developed a scoring system that allows employees to think differently about safety – from taking a reactive approach to one that’s proactive in reducing incidents.

“We came up with a metric essentially that encourages the plants to go after hazard identifications through an audit process, through walking the floor, through ideas that are brought up from the employees,” Tindall says. “So, if they identify a hazard, they’re actually rated on how fast and how good of a countermeasure they put in place.”

With this “risk prevention score,” the emphasis is placed more on improving the safety culture and mentality than on the metric itself, Tindall adds, and the countermeasure becomes a group project based on communication.

When LP Gas visited Quality Steel in August, the company was enjoying a long run of safety success, with no reportable incidents in 2025. In fact, that streak dates back to December 2023 for the West Jordan facility, September 2024 for Cleveland and October 2024 for Fremont.

“We are proud of our record this year,” Dalton says. “It’s something we celebrate.”

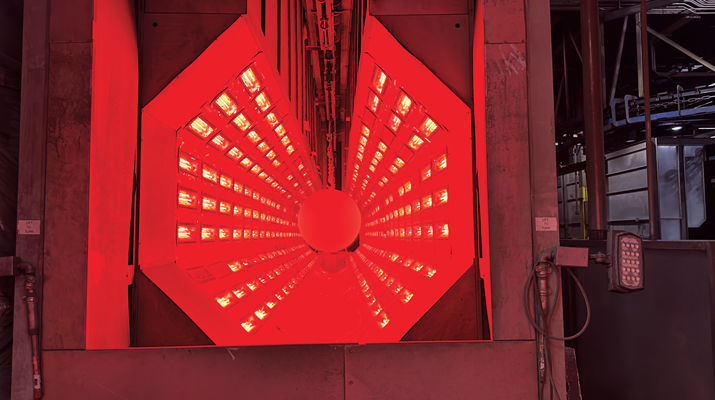

Quality Steel manufactures aboveground and underground propane tanks ranging from 120 gallons to 1,990 gallons. It primarily makes horizontal ASME domestic and small commercial propane tanks in Cleveland and West Jordan. It makes the same products in Fremont, in addition to vertical domestic tanks, dispenser tanks, its largest tanks, as well as anhydrous ammonia tanks. LP Cylinder specializes in propane cylinder recertification and tank refurbishing.

Picou says acquiring AWT’s Fremont and West Jordan plants was “fortuitous” because they provided Quality Steel with strategic locations from which to serve their customers both efficiently and cost-effectively.

Related Articles

Quality Steel completes American Welding & Tank deal