Medford accident leaves questions about supply

Trader’s Corner, a weekly partnership with Cost Management Solutions, analyzes propane supply and pricing trends. This week, Mark Rachal, director of research and publications, discusses the impact of the recent explosion at the ONEOK Medford, Oklahoma, fractionation plant.

Last week, the propane industry got bad news when it was reported that there had been a fire and explosion at the ONEOK Medford, Oklahoma, fractionation plant. Fractionators are critical in providing natural gas liquid supplies, including propane.

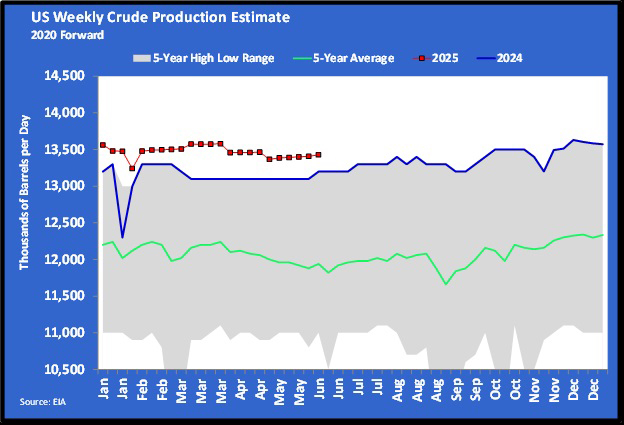

The Medford facility is a 210,000-barrels-per-day-(bpd) fractionator. That is 27 percent of the midcontinent’s fractionation capacity. Oil and gas wells are drilled in an area, and the natural gas and natural gas liquids are gathered from these wells and sent to natural gas processing facilities. The natural gas processing facilities strip out the methane and sell it to natural gas utility companies that in turn sell it to consumers.

The heavier hydrocarbons – ethane, propane, butanes and natural gasoline – remain mixed together in what is known as Y-grade. The Y-grade is sent, usually via pipeline, to the fractionators. The fractionator separates the components of the Y-grade into its fungible, or spec, components. These components are then transported via various means to propane retailers, petrochemical companies, refineries and to export facilities.

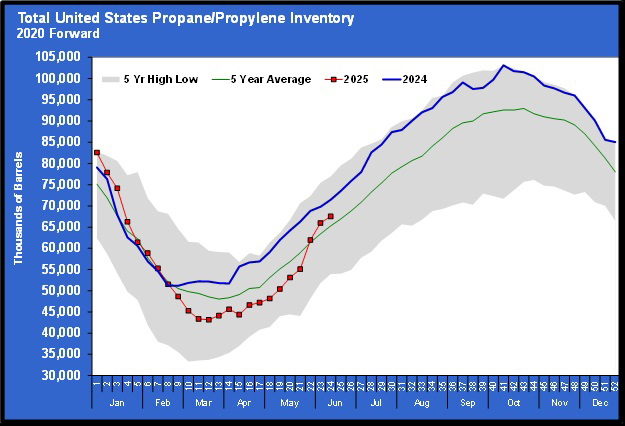

It varies by source makeup of course, but Y-grade is about 42 percent ethane, 28 percent propane, 11 percent normal butane, 6 percent isobutane and 13 percent natural gasoline. At full capacity, Medford would yield about 58,800 bpd of propane. ONEOK had reported its fractionators in the midcontinent were running at 91 percent of capacity. If we apply that number to Medford, then its propane yield was around 53,508 bpd. For the week ending July 8, a couple of days after Medford went offline, U.S. propane production was reported at 2.421 million bpd. That puts Medford at 2.2 percent of U.S. propane supply.

ONEOK will try to reroute the Y-grade from the natural gas processing plants to other fractionators. The degree to which it is successful will determine just how much of the 53,508 bpd of propane supply will be interrupted until the Medford facility can be repaired.

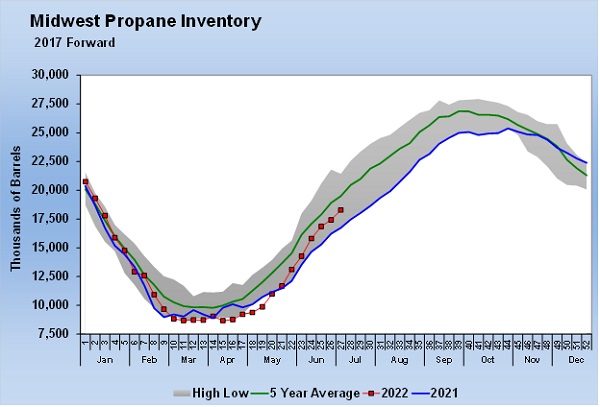

The first concern is obviously for Midwest supply, but much of the Midwest production moves to the coasts, so supply in much of the country could be affected. There is good news and bad news for Midwest propane inventory. The bad news is that the overall trend has been to hold less propane in the Midwest to address potential winter increases in demand. The good news is that after last winter’s tightness, more inventory has been held in the Midwest this year than last.

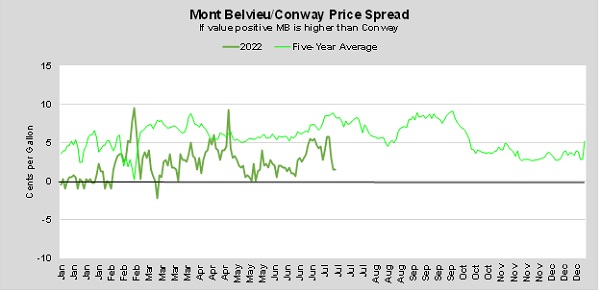

The price spread between Mont Belvieu and Conway is a key component of the inventory story.

For the most part, the spread has been below normal this year. That has promoted keeping barrels in the Midwest. As the inventory shows in Chart 1, Midwest inventory that was setting five-year lows in April and early May improved from late May forward. Midwest inventory gains were significantly better than the Gulf Coast. The spread was expanding in late June and early July, reflecting this development and encouraging the shipment of more propane to the coasts.

But we can see what the Medford incident did to the spread in Chart 2. Right after that incident, the spread dropped from 5¾ cents to just 1½ cents. As we write, the spread is only ½ cent. The incentive to move barrels out of the Midwest is not there now. This incident could keep Conway propane higher than it was running until the market understands the full impact on propane supply. If other fractionators handle the Y-grade, then the spread could start widening again. If they can’t replace Medford, then Mont Belvieu prices could move higher to try to draw barrels from the Midwest, and Conway prices could rise to try to keep the barrels at home.

Of course, with Medford down, the odds of a good crop drying season just went up. Crop drying has been a nonevent the last couple of years, and the high current temperatures would suggest that it will be again this year. But, if you reference Murphy’s Law, it specifically states that if the ONEOK Medford, Oklahoma, fractionator goes down, that crop drying demand will be strong. Okay, so it doesn’t really state that, but it is just the way it tends to go.

Call Cost Management Solutions today for more information about how client services can enhance your business at 888-441-3338 or drop us an email at info@propanecost.com.