Leaders stress propane supply planning in volatile market

It was only logical that an energy market report teeming with volatility would precede messages from industry members professing ways for propane marketers and suppliers to stay ahead of the supply game.

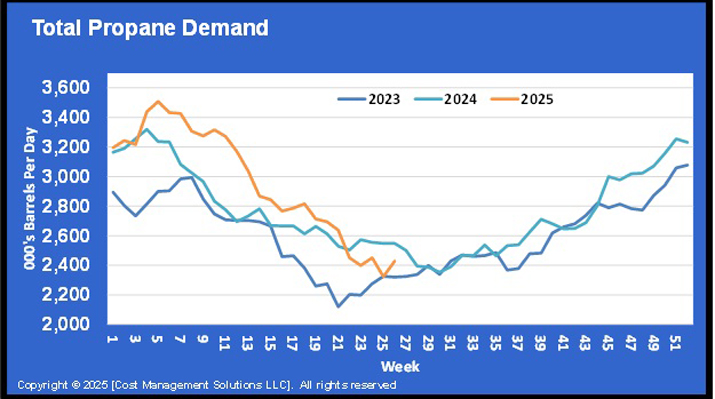

U.S. propane inventory ended last winter about 5 million barrels below 2021 levels. Fast forward about five months, and inventory had rebounded off higher production and lower demand and headed toward the 2022-23 winter about 7.5 million barrels above last year’s levels, reports Rusty Braziel of RBN Energy during a supply-and-demand-focused webinar hosted in September by the National Propane Gas Association (NPGA) and moderated by DD Alexander of Global Gas.

“So even though inventories have increased faster this year, we’re ending up the injection season only slightly better than where we were last year,” he says. “And that’s in a market with a lot of volatility because of what’s going on in the world around us.”

The U.S. propane industry had become part of an international market even before Russia invaded Ukraine early this year. In addition to the weather in Europe, propane marketers now must consider how energy market movements owing to the war could impact their operations.

As Braziel reminds the industry, “We’re entering a propane season with a war in Europe.”

Export levels and the global price of oil are factors for propane marketers to watch in the coming months, he says. Export growth has increased to the point where the U.S. is sending two-thirds of its production to international markets.

“So no one is going to be at all surprised that international markets now can have a much bigger impact on the overall level of U.S. prices than anything that happens in this country,” he says.

Still, propane marketers can take steps to help protect their operations from the volatility, webinar participants say.

Plan, communicate and lock in truck capacity early, says Angela Branchi of Grammer Logistics, adding the latter is critical as LPG competes against the larger chemical markets and other seasonal pushes.

“Each market is different in the U.S. from a truck-capacity perspective,” she says. “Work with your carriers to understand each market independently.”

Kelvin Covington of Growmark stresses the importance of scheduling loads during off-peak hours at terminals. He also suggests using camera shots available to track wait times on Enterprise’s MAPL line as well as NPGA’s PLAN app, which provides real-time information about wait times at U.S. supply points.

Tyler Kelly at CHS cites the propane supply planning tools that suppliers make available to propane marketers.

He also says it’s important to understand the supply availability at secondary terminals amid ongoing stresses on the supply chain.

“Preparation is essential, and that constant communication with your supplier is as important as it’s ever been,” he says.

Todd Eldred of LP Transportation urges companies to work closely with their customers and learn about their propane supply needs throughout the winter.

Featured homepage photo courtesy of Grammer Logistics