Space heating solution builds momentum in residential market

Advanced hydronic, tankless technology is one way for propane to keep pace with electricity in the residential market. (Photo by LP Gas staff)

A competitive propane industry application with roots in the residential market is designed to bring warmth and comfort to homeowners “left out in the cold” when their electric heat pump can’t keep up and the electric heat strip kicks in.

What does the aptly named Heat Pump Helper (HPH) mean for the propane industry and the marketers willing to promote it to their customers?

A group of industry leaders and companies backing the project and pushing HPH toward the finish line say the benefits are many. HPH is a way to protect and grow propane gallons with residential consumers who have adopted the electric heat pump; keep propane as part of the government policy discussion on energy despite efforts to ban gas-fired appliances; and build out applications for propane as a grid-resilient, whole-home power solution.

HPH is based on hydronic heating – a decades-old concept of using water as a source for space heating. But it wasn’t until Randy Doyle and Armistead Mauck began pursuing hydroheat through tankless water heater technology that they saw a propane industry answer to the electric heat pump.

Doyle, an industry veteran who now consults for Holtzman Propane, and Mauck, formerly of Cherry Energy and now working with the Propane Education & Research Council (PERC), teamed up with PERC and the North Carolina Propane Gas Association in 2017 to conduct hydronic test installations that helped prove the concept. Doyle had even considered it two years prior as CFO of Mississippi-based Blossman Gas.

The propane industry has been losing market share to the electric heat pump, especially in the Southeast, for years. Now, with the growing push toward electrification, other parts of the country are looking to adopt the electric heat pump as well. In fact, Maine has set targets to install hundreds of thousands of heat pumps in the next several years in its attempts to move away from fossil fuels.

“Everybody is hyper focused on making the heat pump run in colder climates and make it more efficient, but nobody has come up with a solution for the electric resistor,” Mauck says.

The HPH project team supports the application’s ability to keep propane relevant in the residential home heating market in the years ahead, while a second chapter of the project is designed to leverage propane’s prowess as an off-grid power generation source.

“HPH is our best response to electrification,” Doyle writes in a 2022 column for LP Gas. “It will deserve our industry’s priority and full engagement when we commercialize.”

Test installations have worked to prove the effectiveness of the hydronic, tankless technology, and continue to help the industry learn how to commercialize the product. (Photo by LP Gas staff)

Dual-fuel solution

HPH allows propane marketers to convert homes with electric heat pumps to dual-fuel space heating systems by installing a gas-fired water heater or boiler or using one already on-site. Industry leaders cite the tankless models for their high flow rates and overall technological advancements.

“You can upgrade any heat pump with a dual-fuel system, and the installation will work with any hot water source,” says Stuart Weidie, president and CEO of Blossman Gas, which is testing HPH at multiple company locations.

HPH gives homeowners heating with electric heat pumps a comfortable, high-quality alternative to the electric heat strip – often compared to heating a room with a hair dryer – when temperatures dip below 40 or 50 degrees and a backup heat source is required.

“The heat pump works well in cool days, but when it starts to get good and cold, it will struggle and become less efficient and less effective,” says John Borzoni, director of marketing at Bindus Manufacturing, a HPH project partner.

“Instead of turning on the heat strips, let’s provide a secondary fuel source, a dual-fuel solution, because we have a gas-fired water heater sitting here with energy to spare to provide the space heating needed for the house to keep up,” he says.

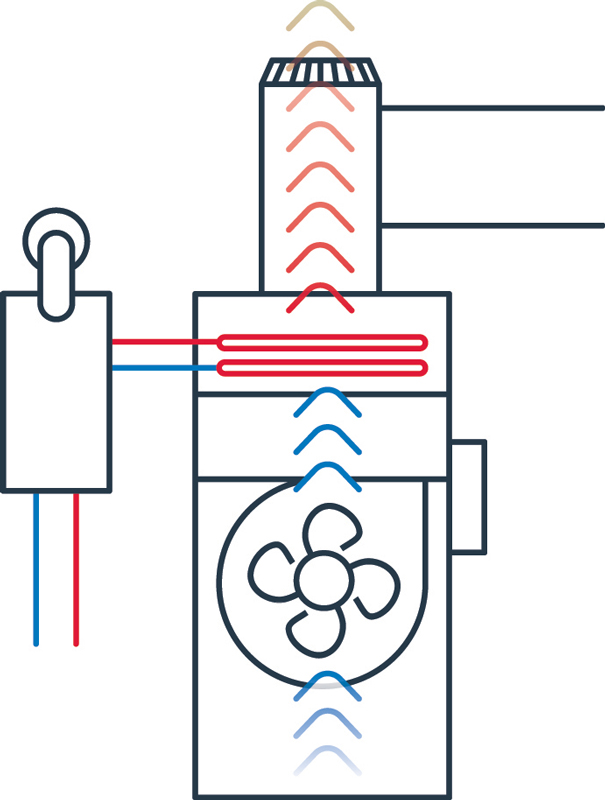

Click to enlarge. With the Heat Pump Helper, water moves from the tankless unit through the hydronic coil, which is mounted to the air handler. (Graphic: Rinnai Corporation)

HPH is unique in the way it integrates the tankless water heater, hydronic coil and air handler to heat the home.

Bindus’ Aquecoil, in existence for 30 years, is a hot water-to-air heat exchanger that mounts directly to all residential-style air handlers. The air-handler-installed HPH moves hot water from the propane tankless water heater through the newly installed Aquecoil to create hot air that is then blown through the existing ductwork to heat the home.

This hydroheat, which requires 4 to 9 gallons per minute of 140- to 180-degree water, depending on system size and hot water source, offers an immediate improvement in a home’s air quality and overall comfort, Bindus says. It doesn’t scorch or dry the air like the electric heat strip; isn’t reliant on outside air temperature that would compromise its dependability; creates warmer air than a heat pump (100 to 125 degrees F versus 85 degrees); and is less expensive than traditional dual-fuel heat pumps with a second-stage furnace. The amount of cost savings, the company adds, will vary depending on the local cost of electricity and propane and the hours of system runtime.

“Hot water is a great way to transmit energy from one place to another,” says Jim Bunsey, director of commercial business development at PERC.

Partners in propane

Bindus is among the companies working closely with the propane industry to develop HPH – Bindus for the hydronic heating coil and Rinnai for the tankless water heater.

Borzoni recalls a telephone call he received two years ago from project leaders asking him to help HPH along. Discussions at the time centered on propane industry concerns about gas-fired appliance bans in favor of the electric heat pump. He initiated a new way of thinking about HPH, which at the time had been focused on new construction.

“We came into the project saying, ‘OK, stop thinking about new construction. Think about the existing inventory of homes that you could convert to dual-fuel systems.’ Whether a heat pump or electric furnace, they were potential opportunity for installing a dual-fuel system,” he says.

Another big change from Bindus’ perspective was the need to create a HPH installation kit for the propane industry. Over the last year and a half, Borzoni says, it developed such a kit. It includes a factory-built plumbing board that preassembles the interconnected piping, so the installer simply connects the hot water source, the hydronic heating coil and the house’s hot and cold water lines to the plumbing board. The kit also contains the appropriate controls and circulator pump, depending on the type of hot water source. The HVAC technician drops the Aquecoil in place in the heat pump air handler supply duct and connects the controls back to the house’s thermostat.

Armistead Mauck is one of the propane industry leaders working to bring “one-button simplicity” to the Heat Pump Helper project so marketers know how to sell and install it. (Photo by LP Gas staff)

The water heater drives the HPH, Mauck explains, as it joins with the plumbing board, pump and control module to facilitate an interaction between the thermostat and air handler.

“The control module is monitoring what the thermostat is saying and what the tankless is doing and putting hot water where and when it’s needed,” adds Kevin Morgan, director of energy for Rinnai America Corp.

Bryan Cordill, director of residential business development at PERC, says Bindus’ “secret sauce” is having a coil that fits every air handler that’s on the market. “We can provide a product for basically every house in America.”

Success with Bindus’ hydronic solution has come on the East Coast, in the Northeast and with mid-Atlantic states, Borzoni says, as the company works closely with wholesale equipment distributors, including R.E. Michel and F.W. Webb.

With HPH, Borzoni says, the propane industry doesn’t have to fight the influx of heat pumps “because they’re coming whether we like it or not.”

“Some marketers are saying, ‘That’s fine; put your heat pump in, but when you need our assistance, we’re there for you.’”

Commercialization efforts

Project leaders have focused on developing HPH from the inside out and with propane marketers in mind. They say success in commercialization means having a propane industry that believes in the product before they sell it, then having a team of technicians comfortable with installing the equipment for customers. A recent round of 10 pilot projects has put HPHs in marketers’ hands and, in some cases, in their homes.

“It’s developed by marketers for marketers and for the consumer,” Mauck says. “That’s what we’re doing in the pilots – getting feedback from our industry. We’re handing it to our service techs.”

Holtzman Propane and Blossman Gas are among the propane marketers involved in pilot projects, not only to gauge HPH’s performance but how the industry can bring it to market.

Doyle says conversations are taking place within Holtzman on how to commercialize HPH, with the pilots also working to explore potential cost reductions so that consumers can get a three-year payback on the installation.

“We have to figure out how we get it out there so that we’re selling it with confidence, doing the installs, the procurement and everything that goes along with it,” Doyle says.

For the propane industry, project leaders say, that means “one-button simplicity” for installation but also knowing how to work successfully alongside allied trade partners.

“We’re now ready to move into the next phase of commercializing this through the propane industry, which is offering the actual system in a readily installable form to those propane marketers that have both the desire and ability to arrange for installation of the equipment,” Borzoni says.

A hybrid heat pump solution was on display at this year’s Southeastern Convention & International Propane Expo in Nashville, Tennessee. (Photo by LP Gas staff)

At this year’s Southeastern Convention & International Propane Expo in Nashville, Tennessee, Borzoni says he met a group of propane marketers prepared to undertake at least part of the sales process with HPH. Doyle described some there as the “early adopters.”

“Many of the propane marketers we talked to are comfortable selling tankless water heaters to residential customers every day of the week, so this is a natural extension of what those marketers are doing already,” Borzoni says. “Now we show your customer how to get more value from the hot water source by making it a dual source – a water heating and space heating piece of equipment.”

Cordill recommends marketers grow with existing customers first, scouring their lists to find current customers with propane water heating applications but without propane central heat.

“Propane home heat offers lots of options,” Cordill says. “This is just another tool in the toolbox for the marketer or HVAC contractor.”

The gallon-growth potential from HPH is impacted by appliance efficiency gains but also dependent on geographic location, project leaders say. The gallon load, PERC adds, is similar to what a high-efficiency propane furnace would burn for a particular climate.

More importantly, Mauck says, is the propane tank sitting in the consumer’s backyard. He calls it the “fuel cell,” the invaluable piece of equipment that protects the consumer from power outages.

Mauck remains committed to developing a grid resilience side to the project.

Timing it right

The HPH team has been active this year to spur the project forward. A group, including leaders at the state and national levels, have met multiple times this year to discuss the merits of HPH and the unique opportunity for the propane industry as it continues to face threats from forced electrification.

Doyle says the propane industry’s response “has to be a whole lot more than messaging and going out there and trying to persuade our legislature on policy. We’ve got to have applications to respond.”

It believes HPH is that application as it eyes commercialization later this year. Weidie, though, as founder of Alliance AutoGas, knows these large-scale projects take time, and the timing must be right. He remains optimistic.

“I hope our industry embraces this technology,” Weidie says. “It’s one of the very few new products that’s come into the market for our industry to increase our gallons, but also to help our customers have more comfortable homes and save money.”

Related:

- Hydroheat: Propane’s best response to electrification

- Rinnai urges DOE to revise proposed efficiency standards

- Propane sharpens edge in battle against electric heat pumps

- New York bans gas in some new buildings

- Beating the electric heat pump

- Water heater market opportunities heating up

- State propane associations face electrification challenges

- Looking back, moving ahead: 8 factors to define propane’s future

For more information on the Heat Pump Helper® by Bindus Manufacturing, please see our website at http://www.HeatPumpHelper.com

Attend NPGA’s Board Meeting in Louisville in October for a session on these technologies and marketers’ perspective on how best to deploy them. NPGA members only!

https://www.npga.org/member-dashboard/